Jewelry Distribution Packaging: Optimizing the Bulk Supply Chain

For distributors managing thousands of SKUs, packaging is not just a product—it is a strategic logistics unit. Efficiency demands standardized dimensions, pallet optimization, and zero-defect consistency at scale.

View Logistics SolutionsWhat Wholesalers & Distributors Really Face

Large order volumes, unpredictable quality from multiple suppliers, SKU complexity, and tight delivery timelines define the wholesale packaging landscape. It is not just about the box; it is about the system behind the custom jewelry box.

Does this resonate with your daily work?

Yes, This Is Our ChallengeCommon Packaging Issues in Wholesale & Distribution

Distributors often encounter inconsistent batch quality, rising unit costs, packing inefficiency, and logistics failures, leading to operational disruption.

Inconsistent Quality

Color shades and logo placements vary between batches, damaging brand trust.

Rising Unit Costs

Hidden defects and repacking labor inflate the real cost per unit.

Packing Inefficiency

Complex assembly slows down warehouse throughput and fulfillment speed.

Logistics Failures

Weak structures collapse under pallet weight during international shipping.

SKU Management Chaos

Non-standardized ring box and necklace box sizes create storage nightmares in distribution centers.

Communication Gaps

Slow supplier responses lead to missed seasonal launch windows.

These problems happen frequently in the wholesale industry.

View Supply Chain CaseHow These Problems Affect Your Business

Ignored inconsistencies and inefficiencies don’t just cost money — they delay shipments, erode trust with retail partners, increase returns, and inflate logistics costs.

- High return rates due to damaged goods.

- Increased labor costs for repacking.

- Lost retail partnerships due to delays.

Unresolved packaging issues impact the bottom line.

Understand the ImpactWhat Wholesalers & Distributors Truly Need from Packaging

Consistency across batches, streamlined SKU management, logistics-friendly designs, cost-control strategies, and supplier reliability are essential.

Successful wholesale packaging starts with the right criteria.

Continue to Solution DirectionThe High-Volume Distribution Framework

An ideal strategy integrates quality control systems, SKU-friendly modular designs, scalable production methods, and logistics compatibility for cost and performance. A successful manufacturing process must fully align with the distribution cycle to eliminate bottlenecks.

These strategy elements ensure packaging reliability.

See Strategic Components in DetailStandardized QC Protocols (AQL 2.5)

Standardized SOPs across all batches.Modular SKU Architecture

Unified profiles (especially for bracelet boxes) for efficient warehousing.ISTA-Certified Transit Testing

Drop & vibration tests for safe transit.Agile Supply Chain Response

3-day sampling for rapid market entry.Why This Packaging Strategy Is Effective

Fast sampling, batch consistency, multi-SKU systems, and logistics-optimized structures reduce returns, shipping damage, and overall cost variance.

Visual proof of strategic improvements.

See Verified Client DataWholesale Packaging in Practical Scenarios

Different use cases demand different packaging approaches: warehouse sorting, distribution bundles, mixed SKU orders, marketplace palletization, and export shipments.

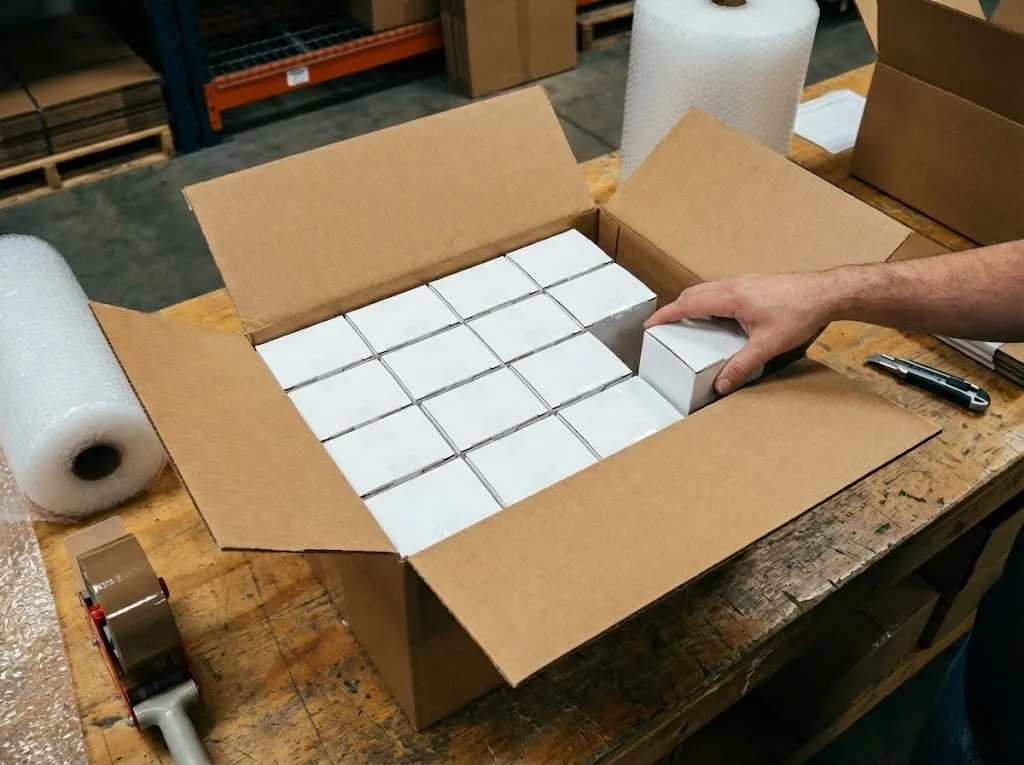

Warehouse Optimization

Stackable rigid boxes designed for high-density storage and quick picking.

Read Supply Chain Case

SKU Bundling

Unified master cartons for mixed jewelry sets to simplify inventory counts.

View [Bracelet] Bundle Specs

Marketplace Pallet

Standardized dimensions compatible with Amazon FBA and retail pallet requirements.

View [PE Film] FBA Solutions

Export Compliance

Materials and labeling fully compliant with US/EU import regulations.

View [Watch Box] StandardsMatch packaging structure to real distribution needs.

Explore Full Packaging Category ListCommon Mistakes in Wholesale Packaging Procurement

Rushing to the lowest unit cost, ignoring marginal logistics costs, overlooking sampling consistency, and failing to align supplier QC processes are common procurement traps.

Avoid these common mistakes to protect your margin and reputation.

See Client Avoidance StrategyReady to Elevate Your Brand with Premium Packaging?

Join hundreds of successful jewelry and accessory businesses who trust YiXin for their custom packaging needs. Get your free sample and quote today.

- Free samples within 3-5 days

- Professional design consultation

- Competitive wholesale pricing

- Global shipping to 50+ countries

- Quality guarantee with certifications

- Dedicated account manager support

Get Your Free Quote Today

Start your journey to premium packaging solutions. Fill out the form below and unlock exclusive benefits for your business.