To achieve standout branding in a saturated luxury market, you must utilize high-end custom boxes, sustainable materials, and intricate luxury finishes. Many jewelry brand owners face the frustrating reality where their exquisite craftsmanship is undermined by generic, uninspired packaging that fails to resonate with high-ticket clients. When your packaging looks identical to every other mass-market competitor, your brand’s perceived value plummets before the customer even sees the product.

By implementing strategic, customizable packaging solutions, you transform a simple transaction into a memorable brand experience that justifies premium pricing and fosters long-term loyalty. If you are wondering who produces jewelry with standout packaging? the answer lies in manufacturers that prioritize technical precision and sensory appeal.

Who produces jewelry with standout packaging and engravings?

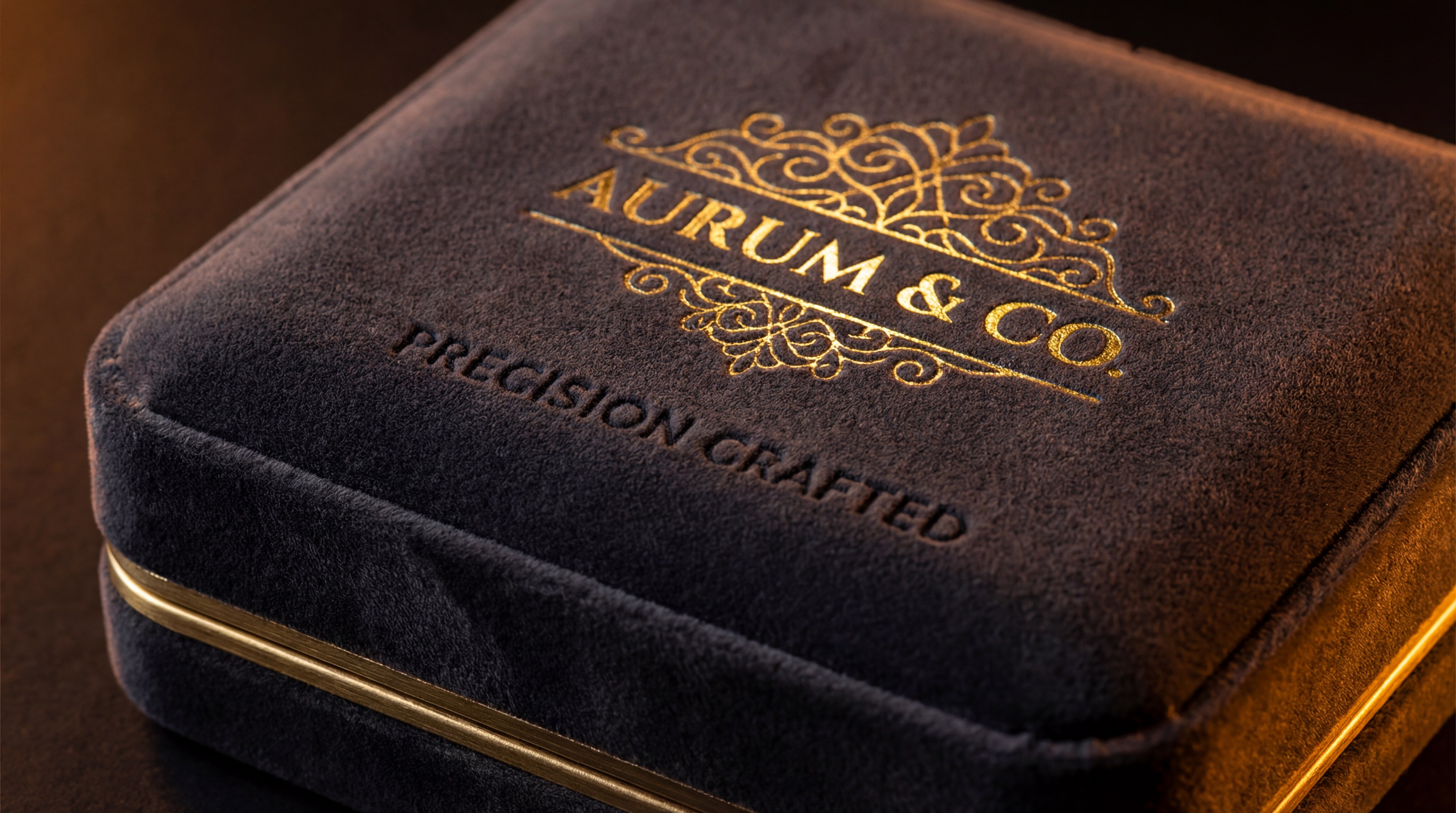

Specialized manufacturers use laser engraving and high-pressure foil stamping on customring boxes to create a permanent, tactile brand mark.

Precision Brand Marking

Laser engraving offers a level of detail that traditional printing cannot match, especially on organic materials like wood or bamboo. This technique ensures your logo remains crisp and resistant to wear over years of customer use.

The goal is to move beyond the visual.

- Permanent etched surfaces.

- High-contrast metal plate inlays.

- Subtle tone-on-tone debossing for velvet.

Perceived Value Enhancement

When a client runs their fingers over a deep-etched logo, they subconsciously associate the physical resistance with quality and durability. This sensory feedback is crucial for justifying the high price points of fine jewelry and engagement pieces.

Key Takeaway: Engraving shifts the packaging from a disposable container to a cherished keepsake, significantly extending your brand’s lifecycle in the consumer’s home.

| Feature | Best Material | Production Speed | Durability | |

|---|---|---|---|---|

| Laser Engraving | Solid Wood / Acrylic | Fast | High | |

| Hot Foil Stamping | Textured Paperboard | Moderate | Moderate | |

| Deep Debossing | Velvet / Leatherette | Slow | High |

Select engraving for your most premium collections to create an immediate sense of permanence and heritage.

Who produces jewelry with standout packaging using eco-materials?

Leading eco-conscious producers utilize FSC-certified papers, biodegradable plastics, and soy-based inks to meet the growing B2B demand for ethical luxury.

Sustainable Structural Integrity

Modern sustainable packaging no longer looks “recycled” in a negative sense; instead, it uses heavy-weight kraft and sugarcane bagasse to provide a sturdy, high-end feel. These materials support the same structural designs as traditional plastics while being fully compostable.

The industry is changing.

- Water-based adhesives that don’t emit VOCs.

- Organic cotton drawstring pouches.

- Recycled ocean-bound plastic inserts.

Aligning Brand Ethics with Aesthetics

B2B buyers are increasingly vetting suppliers based on their carbon footprint and material transparency. By opting for eco-materials, you position your jewelry brand as a forward-thinking leader that values both beauty and responsibility.

Key Takeaway: Sustainable materials allow you to tap into the “Green Premium” market where consumers are willing to pay more for brands with a clear environmental mission.

| Eco-Material | Sustainability Level | Customization Potential | Cost Efficiency | |

|---|---|---|---|---|

| FSC Paperboard | High | Excellent | High | |

| Sugarcane Bagasse | Superior | Moderate | Moderate | |

| Organic Hemp | High | Moderate | Low |

Choose FSC-certified paperboard for high-volume orders where you need to balance environmental impact with budget-friendly customization.

Who produces jewelry with standout packaging and textures?

Producers specializing in “sensory branding” offer premium earring boxes featuring soft-touch lamination, flocked velvet, and embossed leatherette surfaces.

The Psychology of Touch

The first physical interaction a customer has with your brand is the surface of the box. A soft-touch matte finish or a heavy grain leatherette communicates luxury and sophistication before the lid is even lifted.

It’s all about the unboxing “feel.”

- Micro-textured papers that mimic linen.

- Ultra-soft velvet flocking for scratch prevention.

- High-gloss UV spot coatings for contrast.

Durability and Resistance

High-quality textured finishes aren’t just for show; they also protect the packaging from fingerprints, scuffs, and moisture during shipping. This ensures that the presentation remains flawless from the warehouse to the customer’s doorstep.

Key Takeaway: Utilizing diverse textures creates a multi-sensory experience that makes your brand feel more expensive and well-considered than competitors using flat-finish paper.

| Texture Type | Sensory Impact | Fingerprint Resistance | Luxury Perception | |

|---|---|---|---|---|

| Soft-Touch Matte | High (Velvety) | High | Excellent | |

| Linen Embossed | Moderate (Textile) | Superior | High | |

| High Gloss UV | High (Visual) | Low | Moderate |

Incorporate soft-touch matte finishes for e-commerce brands to minimize visible scuffs during the shipping process.

Who produces jewelry with standout packaging and creative shapes?

Innovative manufacturers help you move beyond the standard square by producing hexagonal, circular, and modular jewelry boxes designed to capture attention.

Breaking the Retail Grid

In a retail setting, a uniquely shaped box disrupts the visual patterns on the shelf, forcing the customer’s eye to linger on your product. Geometric shapes like hexagons offer a modern, architectural feel that suits contemporary jewelry designers perfectly.

Don’t be afraid to be different.

- Octagonal engagement ring holders.

- Modular stacking boxes for jewelry sets.

- Teardrop-shaped pendant cases.

Structural Innovation

Creative shapes require expert engineering to ensure the lid remains secure and the interior lining fits the unusual dimensions perfectly. Working with a producer who understands die-cutting and structural integrity is essential for these complex designs.

Key Takeaway: Distinctive shapes provide immediate brand recognition, often becoming as iconic as the jewelry itself (much like the “blue box” phenomenon).

| Box Shape | Branding Style | Manufacturing Complexity | Shelf Space Efficiency | |

|---|---|---|---|---|

| Hexagon | Modern / Geometric | Moderate | Moderate | |

| Round | Classic / Romantic | High | Low | |

| Modular Square | Professional / Tech | Moderate | High |

Utilize hexagonal or round shapes for boutique retail displays where visual differentiation is your primary marketing tool.

Who produces jewelry with standout packaging in custom colors?

Manufacturers offering custom floating display boxes use precise Pantone matching to ensure your packaging color aligns perfectly with your brand’s digital and print identity.

Pantone Accuracy in Production

Maintaining color consistency across different materials—such as a paper box, a silk ribbon, and a velvet insert—is the mark of a superior production partner. Even a slight variation in hue can make your brand look uncoordinated and unprofessional.

Consistency is your strongest asset.

- Deep jewel tones for luxury positioning.

- Pastel palettes for “Gen Z” or bridal brands.

- Metallic finishes for high-fashion collections.

Emotional Color Response

Colors evoke specific emotions: navy blue suggests trust and tradition, while a vibrant terracotta might suggest artisanal, handmade quality. Choosing a custom color scheme allows you to direct the customer’s emotional state during the unboxing.

Key Takeaway: A custom color palette acts as a silent ambassador for your brand, making your shipments instantly recognizable from the moment the mailer is opened.

| Color Category | Target Audience | Emotional Impact | Versatility | |

|---|---|---|---|---|

| Jewel Tones | High-Net-Worth | Trust / Opulence | High | |

| Nudes / Earth | Minimalist / Eco | Calm / Sincerity | Moderate | |

| Bright / Neon | Young / Trendy | Energy / Boldness | Low |

Define a signature brand color early and stick to it across all packaging touchpoints to build lasting visual equity.

Who produces jewelry with standout packaging and display windows?

Specialized firms create “windowed” packaging using high-clarity PET or acrylic to allow the jewelry to serve as its own hero while staying protected from dust and oils.

Visual Merchandising Integrated

A transparent window eliminates the “barrier of entry” for the customer, allowing them to admire the jewelry’s sparkle and detail immediately. This is particularly effective for high-inventory retail environments where you want to minimize the handling of products.

Let the jewelry speak for itself.

- Beveled glass-look acrylic windows.

- PE film “floating” frames for 360-degree views.

- Frosted window borders for a soft reveal.

Protective Clarity

Modern window materials are treated with anti-scratch and anti-static coatings. This ensures that even after months on a shelf, the view of your diamond pendant or gold earrings remains crystal clear without attracting lint.

Key Takeaway: Display windows bridge the gap between storage and presentation, making the packaging a functional part of your retail merchandising strategy.

| Window Material | Clarity | Scratch Resistance | Cost Point | |

|---|---|---|---|---|

| Acrylic | Superior | High | Premium | |

| PET Film | High | Moderate | Economic | |

| Bio-Acetate | Moderate | Low | Sustainable |

Use high-clarity acrylic windows for high-value pendants to maximize light refraction and “sparkle” in retail cases.

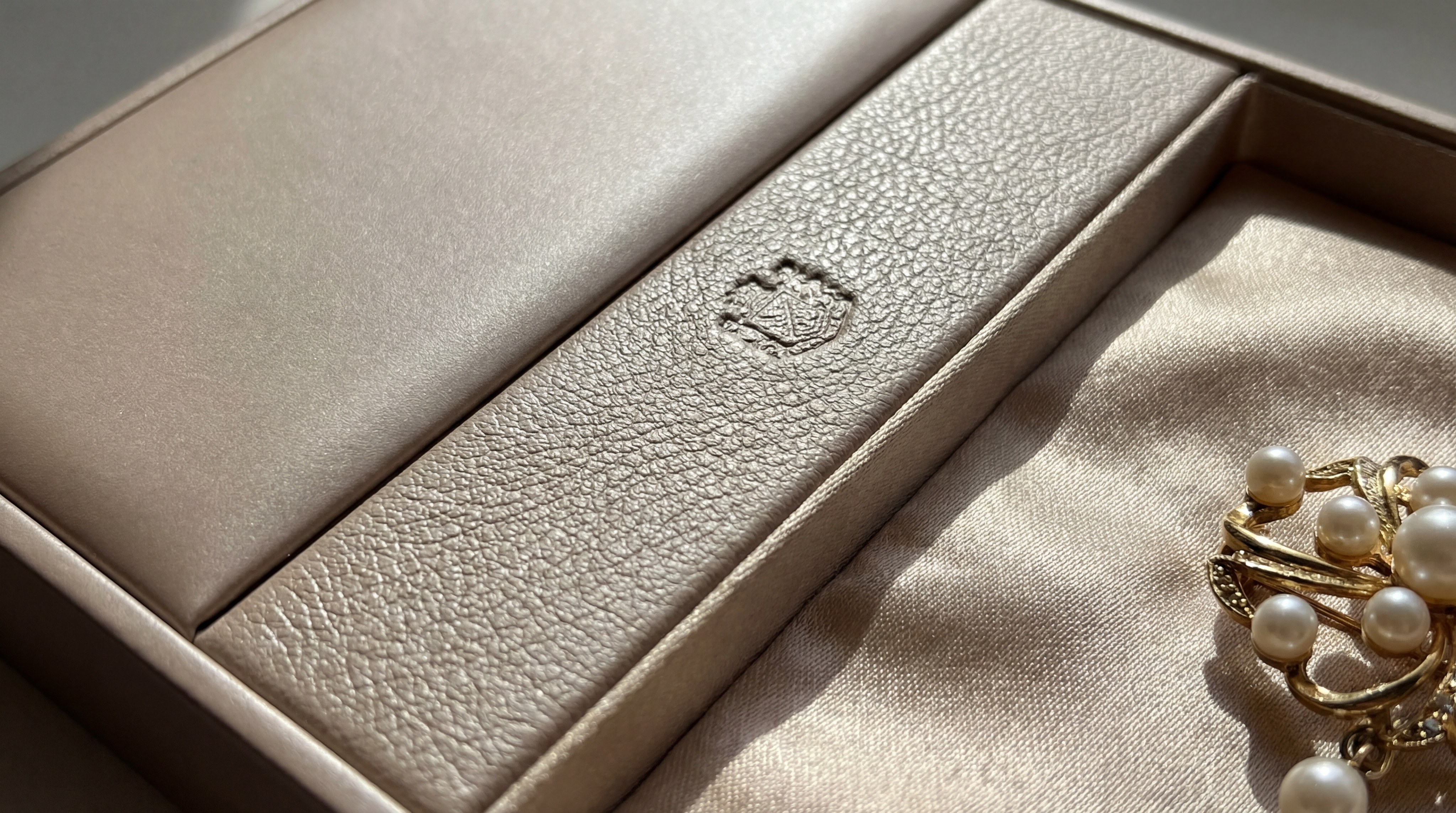

Who produces jewelry with standout packaging and custom linings?

Producers of high-end necklace boxes focus on internal engineering, offering die-cut EVA foam and microfiber linings that secure jewelry during transit.

Structural Security

The interior of your packaging must be engineered to the exact dimensions of your jewelry. A custom-cut foam insert ensures that a heavy necklace doesn’t shift or tangle during the turbulence of international shipping.

It’s what’s inside that counts.

- High-density EVA foam for impact absorption.

- Microfiber cloths to prevent tarnish and oxidation.

- Silk-wrapped pillows for luxury watch and bangle sets.

Interior Branding Surface

The lining is also a prime location for secondary branding. Subtle silver foil logos on the interior lid or branded patterns on the foam surface provide a sophisticated “second layer” of brand discovery for the customer.

Key Takeaway: Custom linings prevent the “rattle” associated with cheap packaging, replacing it with a weighted, silent, and secure feel that signals high-end engineering.

| Lining Material | Best Use Case | Protection Level | Aesthetic Feel | |

|---|---|---|---|---|

| EVA Foam | Heavy Necklaces | Superior | Modern | |

| Suede / Microfiber | Fine Gold / Silver | High | Classic Luxury | |

| Satin | Light Earrings | Moderate | Romantic |

Invest in custom-cut inserts for all e-commerce shipments to eliminate the risk of product damage and costly returns.

Who produces jewelry with standout packaging and security?

Innovative manufacturers incorporate hidden security features such as magnetic closures and tamper-evident seals to protect high-value jewelry from theft and diversion.

Hidden Closure Engineering

Strong N52 neodymium magnets can be hidden beneath the paperboard, providing a satisfying “snap” when the box closes. This ensures the lid stays shut during transit without the need for unsightly exterior tape or bands.

Security should be invisible.

- Magnetic “auto-lock” mechanisms.

- Pressure-sensitive security seals for high-value shipments.

- RFID-integrated tags for inventory tracking.

Enhancing Customer Trust

When a customer receives a box that feels securely sealed and structurally sound, their trust in your brand increases. For B2B suppliers, providing tamper-evident packaging is a critical requirement for shipping loose stones or high-carat jewelry.

Key Takeaway: Security features protect your bottom line by reducing shipping losses while simultaneously signaling to the customer that their purchase is valuable and handled with care.

| Security Feature | Mechanism | Visibility | Brand Impact | |

|---|---|---|---|---|

| Magnetic Closure | Neodymium Magnets | Invisible | High Satisfaction | |

| Tamper Seal | Void Pattern | High | High Trust | |

| RFID Integration | Digital Chip | Invisible | Logistics Power |

Combine magnetic closures with custom-printed outer sleeves for the ultimate balance of security and high-end presentation.

Who produces jewelry with standout packaging and dual uses?

Top-tier jewelry box manufacturers are now designing “upcyclable” packaging that serves as a permanent jewelry organizer or travel case.

Sustainability Through Longevity

The most sustainable package is the one the customer never throws away. By designing a box with removable inserts, you transform the packaging into a functional travel case or home storage solution.

Give your box a second life.

- Removable trays for versatile storage.

- Mirror-integrated lids for travel convenience.

- Stacking modular designs for growing collections.

Continuous Brand Exposure

Every time your customer uses their “packaging” as a travel case, they are re-exposed to your logo. This persistent brand presence keeps your jewelry top-of-mind for their next purchase or when friends ask for recommendations.

Key Takeaway: Multi-purpose design significantly increases the “utility value” of your packaging, justifying higher production costs through enhanced customer retention.

| Dual Use Design | Function | Lifetime Value | Customer Utility | |

|---|---|---|---|---|

| Removable Tray | Home Organizer | High | Superior | |

| Mirrored Lid | Travel Case | Moderate | High | |

| Stackable Base | Modular Storage | High | Moderate |

Market your packaging as a “Free Travel Case” to increase conversion rates and highlight your commitment to circular design.

Who produces jewelry with standout packaging and brand extras?

Comprehensive producers provide the “little extras” like customized ribbons, wax seals, and branded certificates that complete the luxury unboxing experience.

The Art of the Reveal

The unboxing process should be a ritual. Using branded tissue paper and custom wax seals creates layers of discovery, slowing the customer down and building anticipation for the moment they finally see the jewelry.

Small details make the biggest impact.

- Grosgrain or satin ribbons with embossed logos.

- Parchment certificates of authenticity.

- Hand-poured wax seals for a “bespoke” feel.

B2B Branding Consistency

For B2B distributors, these extras allow you to provide a “turnkey” solution for retail partners. Providing branded bags and care cards alongside the jewelry boxes ensures a consistent brand voice across all sales channels.

Key Takeaway: Additional elements like custom ribbons and seals act as the final “polish” on your brand, separating professional jewelry houses from amateur sellers.

| Extra Element | Material Option | Visual Impact | Emotional Connection | |

|---|---|---|---|---|

| Branded Ribbon | Satin / Grosgrain | High | Elegant | |

| Wax Seal | Flexible Resin | Superior | Bespoke | |

| Authenticity Card | Linen Cardstock | Moderate | Trust |

Always include a branded care card or certificate of authenticity to reinforce the value and craftsmanship of your jewelry.

Conclusion

Transforming your jewelry presentation through these 10 customizable solutions solves the critical B2B pain point of brand anonymity. By integrating high-end finishes, sustainable engineering, and functional dual-use designs, you move beyond being a mere vendor and become a luxury brand with staying power. The investment in packaging is an investment in your brand’s future equity and customer trust. To begin building your custom collection and elevating your brand’s physical presence, contact us today and let our design experts help you create a packaging strategy that truly stands out.

FAQ

Can I order eco-friendly materials without sacrificing the luxury feel?Yes. Modern sustainable options like FSC-certified heavy paperboard and sugarcane bagasse are engineered to provide the same structural weight and high-end tactile experience as traditional luxury materials.

What’s the best customization technique for small logo details?Laser engraving or high-definition foil stamping are the superior choices. These methods maintain crisp lines even on intricate logos, whereas traditional screen printing may bleed on textured surfaces.

Does custom packaging significantly affect shipping costs?Judgment: It depends on the design. While custom shapes may increase volumetric weight, choosing foldable “flat-pack” luxury designs or lightweight high-density foam can actually optimize shipping costs compared to bulky, off-the-shelf alternatives.

How long does a typical custom production run take?Judgment: Generally 4 to 8 weeks. This timeline includes the structural design phase, prototyping, material sourcing, and final mass production with quality control checks.

Can sustainable materials be color-matched to my brand?Yes. Using water-based and soy-based inks, manufacturers can achieve precise Pantone matching on recycled kraft and other eco-friendly surfaces without compromising the material’s recyclability.