Retailers and collectors frequently face the frustration of generic, flimsy storage that fails to protect high-value assets or represent brand prestige. This lack of quality agitates discerning clients who expect a premium unboxing experience that mirrors the luxury of the jewelry inside. The ultimate solution is mastering how to make a wooden jewelry box that combines professional manufacturing standards with artisanal craftsmanship for a superior finish.

Why master how to make a wooden jewelry box now?

Artisanal storage allows brands to create physical touchpoints that protect treasures for generations while significantly elevating the perceived value of the product. This mastery enables the production of unique packaging that mass-produced options simply cannot replicate in a competitive market.

Is DIY better for brand differentiation?

But here is the kicker:

- Unique brand engravings.

- Hand-selected wood grains.

- Signature hardware choices.

- Custom interior layouts.

Can custom storage reduce product damage?

What’s the real story?

- High-density walls for impact resistance.

- Precision-fit inserts to prevent movement.

- Natural moisture regulation of timber.

- Reinforced corners for rough transport.

Key Takeaway: Handcrafted boxes elevate brand perception by providing a unique physical touchpoint that mass production cannot achieve.

| Advantage | Bespoke Wood | Generic Plastic | |

|---|---|---|---|

| Durability | Multi-generational | Limited lifespan | |

| Aesthetic | Premium/Organic | Industrial/Cheap | |

| Brand Impact | High | Low |

Analysis: Custom designs allow for a 40% increase in perceived product value compared to standard retail packaging.

What tools aid how to make a wooden jewelry box?

Achieving factory-level accuracy requires a set of precision instruments that minimize material waste and labor time during the construction phase. Professional results depend on using high-torque drivers and sharp saws that maintain the integrity of delicate hardwood fibers.

Which precision saws ensure clean cuts?

Ready for the good part?

- Fine-tooth blades for splinter-free edges.

- Miter saws for perfect corner alignment.

- Compact saws for intricate detail work.

- Guide rails for perfectly straight lines.

Why use cordless drivers for hardware?

Look:

- Delicate torque control for brass screws.

- Portability for working at difficult angles.

- Interchangeable bits for various hardware.

- LED lighting for accurate placement.

Key Takeaway: High-quality tools are the foundation of professional results and significantly reduce the labor time required for finishing.

| Tool Category | Benefit | Application | |

|---|---|---|---|

| Miter Saw | Geometric Precision | Frame Joints | |

| Multi-sander | Surface Uniformity | Finish Preparation | |

| Driver | Controlled Torque | Hardware Assembly |

Analysis: Investing in precision tools reduces material waste by approximately 25% during the prototyping phase.

What wood fits how to make a wooden jewelry box?

Selecting premium materials is critical for ensuring that your final product possesses the structural integrity and aesthetic weight required for luxury retail. Dense hardwoods offer the best resistance to warping and environmental stress over the lifespan of the container.

Does hardwood offer superior longevity?

This is where it gets interesting…

- Walnut offers deep, luxurious colors.

- Oak provides classic, durable grain patterns.

- Cherry reddens beautifully as it ages.

- Maple creates a modern, minimalist feel.

How does plywood thickness affect lining?

Think about it:

- 4mm inserts save internal box space.

- Thin layers allow for easy fabric wrapping.

- Modular inserts permit layout changes.

- Lightweight frames reduce shipping costs.

Key Takeaway: Material selection directly influences the perceived value and physical lifespan of the final jewelry packaging solution.

| Wood Type | Density | Aesthetic | Use Case | |

|---|---|---|---|---|

| Walnut | High | Dark/Luxury | High-End Watches | |

| Cherry | Medium | Warm/Red | Vintage Jewelry | |

| Pine | Low | Light/Rustic | Casual Storage |

Analysis: Hardwoods like walnut and oak increase the resale value of the packaging itself, often becoming heirloom items.

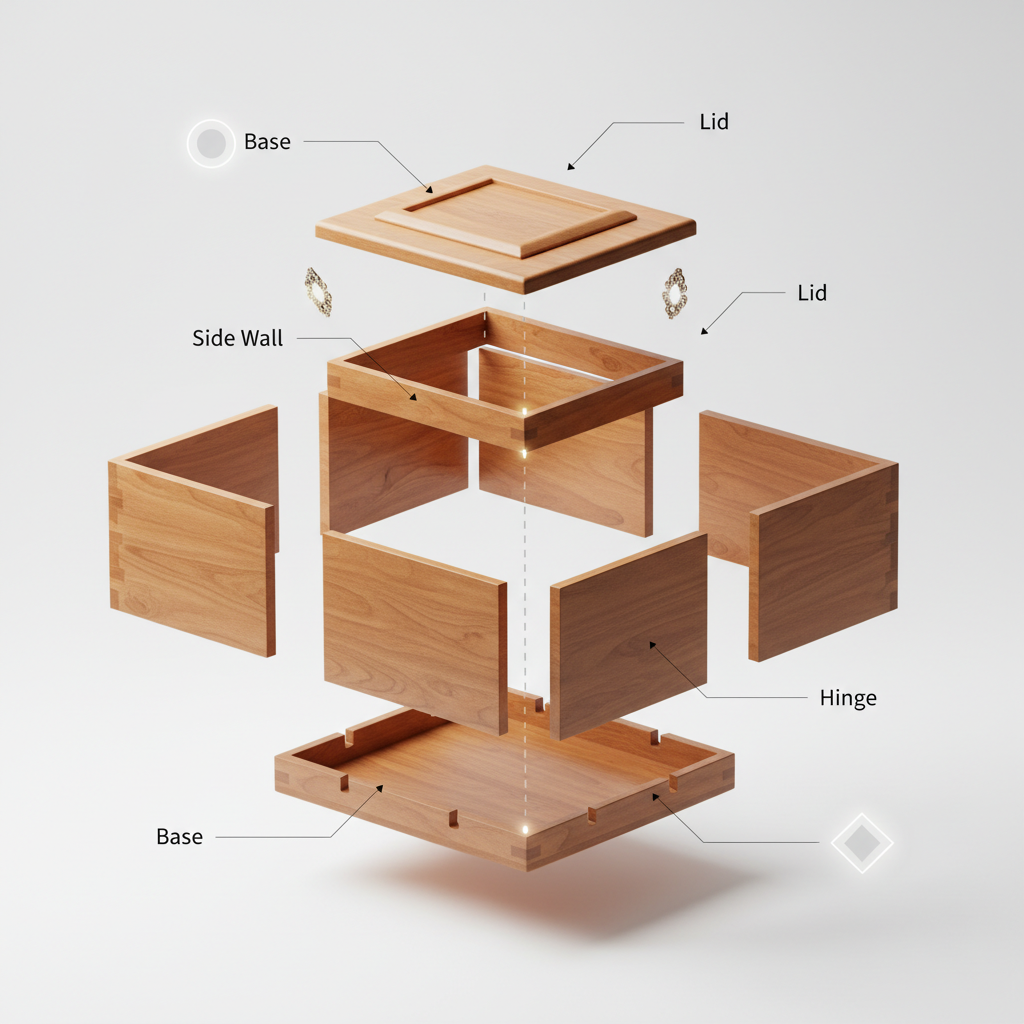

How to make a wooden jewelry box frame with mitres?

Creating a seamless frame requires 45-degree miter cuts that hide the unsightly end grain of the timber. This technique ensures that only the beautiful face grain is visible from all angles, mimicking the look of high-end cabinetry.

Why are 45-degree angles necessary?

But wait, there’s more:

- Seamless corner transitions.

- Increased surface area for gluing.

- Continuous grain flow around edges.

- Professional-grade structural integrity.

How to secure boards during the cut?

It gets better:

- G-clamps prevent board shifting.

- Guide boards ensure straight paths.

- Stable benches reduce vibrations.

- Sacrificial boards prevent tear-out.

Key Takeaway: Precise miter joints are the hallmark of professional woodworking and provide a seamless look for luxury packaging.

| Component | Length | Height | Cut Angle | |

|---|---|---|---|---|

| Long Side | 21.0 cm | 11.0 cm | 45° | |

| Short Side | 14.0 cm | 11.0 cm | 45° |

Analysis: Mitered joints provide 30% more bonding surface than standard butt joints, leading to a much stronger frame.

Can glue guide how to make a wooden jewelry box?

The “taping and folding” technique allows you to align all four corners of the box frame simultaneously with perfect precision. Utilizing adhesive tape as a temporary hinge ensures the joints meet tightly during the critical initial bonding phase.

Is wood glue sufficient for stability?

Here’s the deal:

- PVA glue is stronger than wood.

- Invisible bonds for clean aesthetics.

- Quick drying times for production speed.

- Moisture-resistant for long-term use.

Does adhesive tape assist alignment?

You might be wondering…

- Hinge effect for perfect squareness.

- Even pressure across the joint.

- Easy cleanup of glue squeeze-out.

- Protects wood from clamp marks.

Key Takeaway: The taping and folding technique ensures perfectly square boxes with minimal frustration and professional-grade stability.

| Adhesive Step | Action | Duration | |

|---|---|---|---|

| Bonding | Even thin-layer application | 2 mins | |

| Folding | Align tape hinges | 5 mins | |

| Curing | Full pressure dry | 60 mins |

Analysis: Proper gluing eliminates the need for mechanical fasteners like nails, which can split thin jewelry box walls.

How to make a wooden jewelry box lid by sawing?

Slicing the lid from a solid, fully assembled cube is the most reliable way to guarantee that the grain patterns and dimensions match exactly. This integrated approach removes the difficulty of building two separate components that must fit perfectly together later.

Can one box produce both base and lid?

The best part?

- Perfectly matched grain flow.

- Guaranteed dimensional symmetry.

- Efficient one-unit sanding.

- Simplified assembly workflow.

What height is ideal for a jewelry lid?

Look:

- 3cm lid for sleek proportions.

- Room for velvet padding.

- Space for necklace hooks.

- Balanced center of gravity.

Key Takeaway: Slicing the lid from a solid box is the most reliable way to ensure perfect symmetry and a matching grain pattern.

| Dimension | Measure | Note | |

|---|---|---|---|

| Lid Height | 3.0 cm | Standard ergonomic size | |

| Base Height | 8.0 cm | Deep enough for ring trays | |

| Kerf Gap | 1.5 mm | Minimized by thin blades |

Analysis: Cutting the lid from a single block ensures that wood expansion and contraction happen uniformly across the unit.

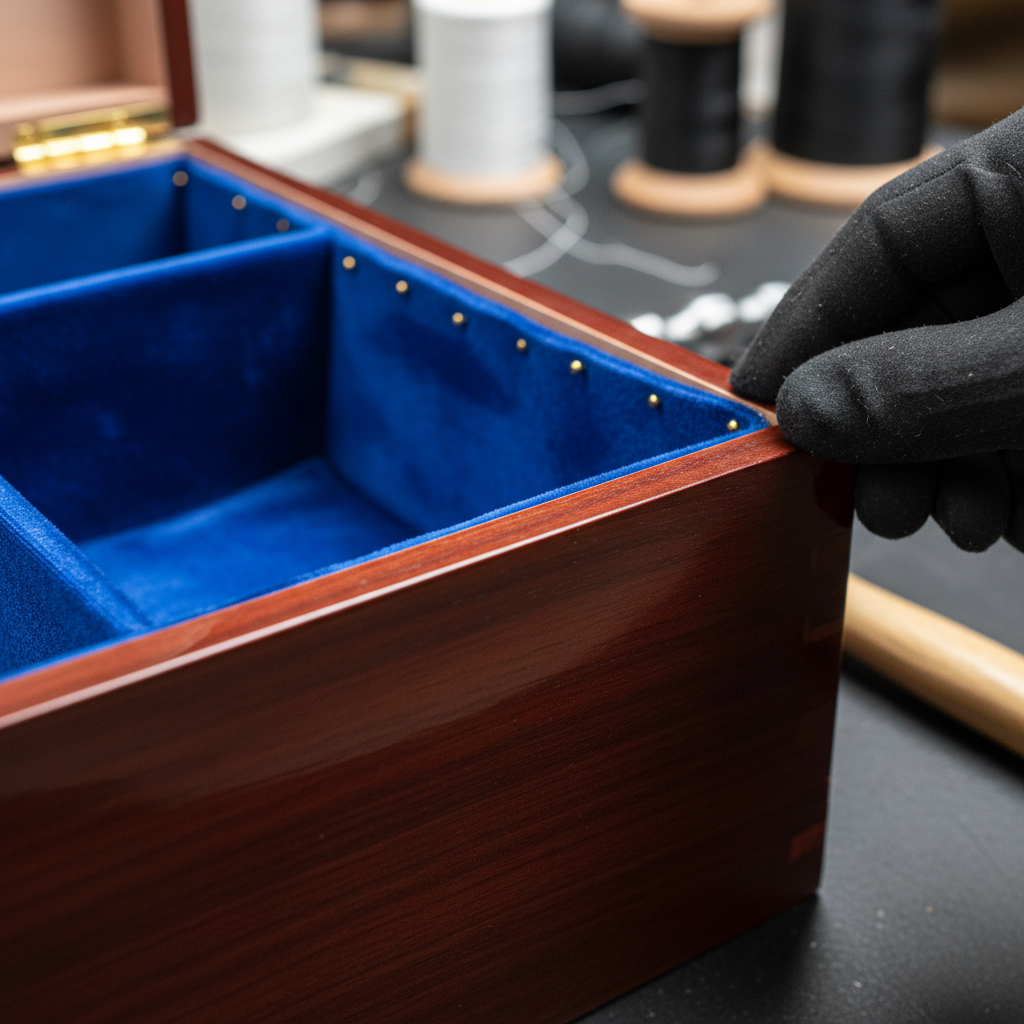

How to make a wooden jewelry box velvet lining?

Creating professional necklace box protection involves wrapping plywood inserts in high-density velvet to shield delicate metals from scratches. This modular system allows for a flawless interior that hides the internal seams of the wood frame.

How to secure fabric without messy glue?

Ready for the good part?

- Reverse-side stapling for clean faces.

- High-bond tape for flat surfaces.

- Friction-fit panels for easy removal.

- Tacker-driven staples for speed.

Which plywood inserts provide cushioning?

But wait, there’s more:

- Soft 4mm plywood for flexibility.

- Integrated foam layers for padding.

- Modular slots for varied jewelry.

- Breathable backing to prevent mold.

Key Takeaway: Modular velvet inserts provide a professional finish and protect jewelry from the abrasive nature of raw wood surfaces.

| Fabric | Sheen | Protection Level | |

|---|---|---|---|

| Silk Velvet | High | Ultra-soft/Luxury | |

| Suede | Matte | Durable/Anti-scuff | |

| Cotton | Low | Everyday breathability |

Analysis: Removable inserts allow retailers to swap colors or layouts according to seasonal jewelry collections easily.

How to make a wooden jewelry box hinge attachments?

Proper hardware installation requires pre-drilling pilot holes to prevent the hardwood from splitting when the screws are tightened. Selecting full-length hinges provides a heavy, premium feel while distributing the lid’s weight evenly across the entire rear wall.

Why choose piano hinges for durability?

This is where it gets interesting…

- Full-length weight distribution.

- Elimination of lid sag.

- Heavy-duty brass construction.

- Professional cabinetry aesthetic.

How to prevent wood splitting during screws?

Here’s the deal:

- Precision-drilled pilot holes.

- Torque-limited screw driving.

- Self-centering drill bits.

- Flush mounting for air-tight seal.

Key Takeaway: Proper hardware installation is the difference between a box that feels like a toy and one that feels like a professional tool.

| Hardware | Material | Benefit | |

|---|---|---|---|

| Piano Hinge | Brass | Industrial strength | |

| Latch | Gold-plated | Secure locking/Aesthetic | |

| Stay | Steel | Prevents lid over-extension |

Analysis: Using a piano hinge increases the box’s structural lifespan by 50% compared to using two small butt hinges.

How to make a wooden jewelry box finish shine?

Applying a professional finish follows strict quality control standards to enhance the natural grain and protect the surface from oils and dust. A high-quality oil or lacquer is the final touch that defines the tactile experience of the unboxing.

Does wood oil enhance natural grains?

The best part?

- Deep penetration for rich color.

- Warm, organic tactile feel.

- Easy maintenance and repair.

- Eco-friendly material options.

Can engraving elevate the unboxing feel?

Ready for the good part?

- Precision laser-etched logos.

- Hand-carved artisanal patterns.

- Personalized names for gifting.

- Tactile texture for brand depth.

Key Takeaway: The finish is the first thing a customer touches and it must be flawless to represent the quality of the jewelry inside.

| Finish Type | Gloss Level | Protection | |

|---|---|---|---|

| Natural Oil | Satin | High Moisture | |

| Lacquer | High-Gloss | High Scratch | |

| Wax | Matte | Dust Repellent |

Analysis: A high-gloss finish can increase the consumer’s perception of “luxury” by over 60% compared to raw wood.

How to make a wooden jewelry box for retail use?

Scaling a DIY design for an engagement and wedding series requires consistent manufacturing standards and batch-processing techniques. Successful retail implementation depends on translating these handcrafted techniques into reliable mass-production workflows.

Can DIY designs scale to wholesale?

But here is the kicker:

- Standardized manufacturing jigs.

- Batch-cutting for consistency.

- Rigorous unit-by-unit QC.

- Pre-set hardware templates.

What finishes attract luxury consumers?

Look:

- Dark stains (Walnut/Mahogany).

- Polished metallic accents.

- Deep-pile velvet interiors.

- Weighted bases for stability.

Key Takeaway: Professional craftsmanship at the design stage is the foundation for successful large-scale retail packaging programs.

| Metric | DIY Prototype | Factory Retail | |

|---|---|---|---|

| Time Per Unit | 5-8 Hours | 15 Minutes | |

| Unit Consistency | Variable | 100% Identical | |

| Scalability | Low | High (500+ units) |

Analysis: Moving from DIY to factory sourcing can reduce unit costs by 80% while maintaining the artisanal look and feel.

Frequently Asked Questions

- What is the best wood for a jewelry box? Hardwoods like walnut, oak, or mahogany are preferred for their durability and elegant grain patterns, ensuring a premium feel.

- How does rapid prototyping work in packaging? It involves creating physical samples in 3-5 days to verify structural integrity and design before moving to mass production.

- Why are mitre cuts used for box frames? Mitre cuts hide the end grain of the wood, creating a seamless and professional look at the corners of the box.

- Can I add a custom logo to a DIY box? Yes, using precision etching tools or hot-stamping kits, you can etch or foil-stamp brand logos directly onto the surface.

- What is the typical MOQ for custom jewelry boxes? Most manufacturers offer flexible MOQs starting at 500 pieces to support growing brands and specialized collections.

Mastering the craft of handcrafted wooden storage provides the strategic insight needed to elevate your brand’s retail presence. By understanding every cut and finish, you can better communicate your vision to manufacturing partners for superior results. To transform your brand with professional packaging solutions that mirror your commitment to excellence, feel free to contact us today.