Your cherished jewelry often ends up in a tangled mess at the bottom of a drawer or hidden in uninspiring plastic organizers that offer zero protection against oxidation and scratches. This lack of organization doesn’t just waste your time in the morning; it actively devalues your sentimental investments, leading to broken chains and duller gemstones. The market offers “luxury” boxes at exorbitant prices, but they rarely match your specific collection’s needs or the aesthetic of your home. Learning how to make your own jewelry box allows you to bridge the gap between high-end craftsmanship and functional personalization, resulting in a bespoke sanctuary for your treasures that lasts for generations.

Why start with a blueprint?

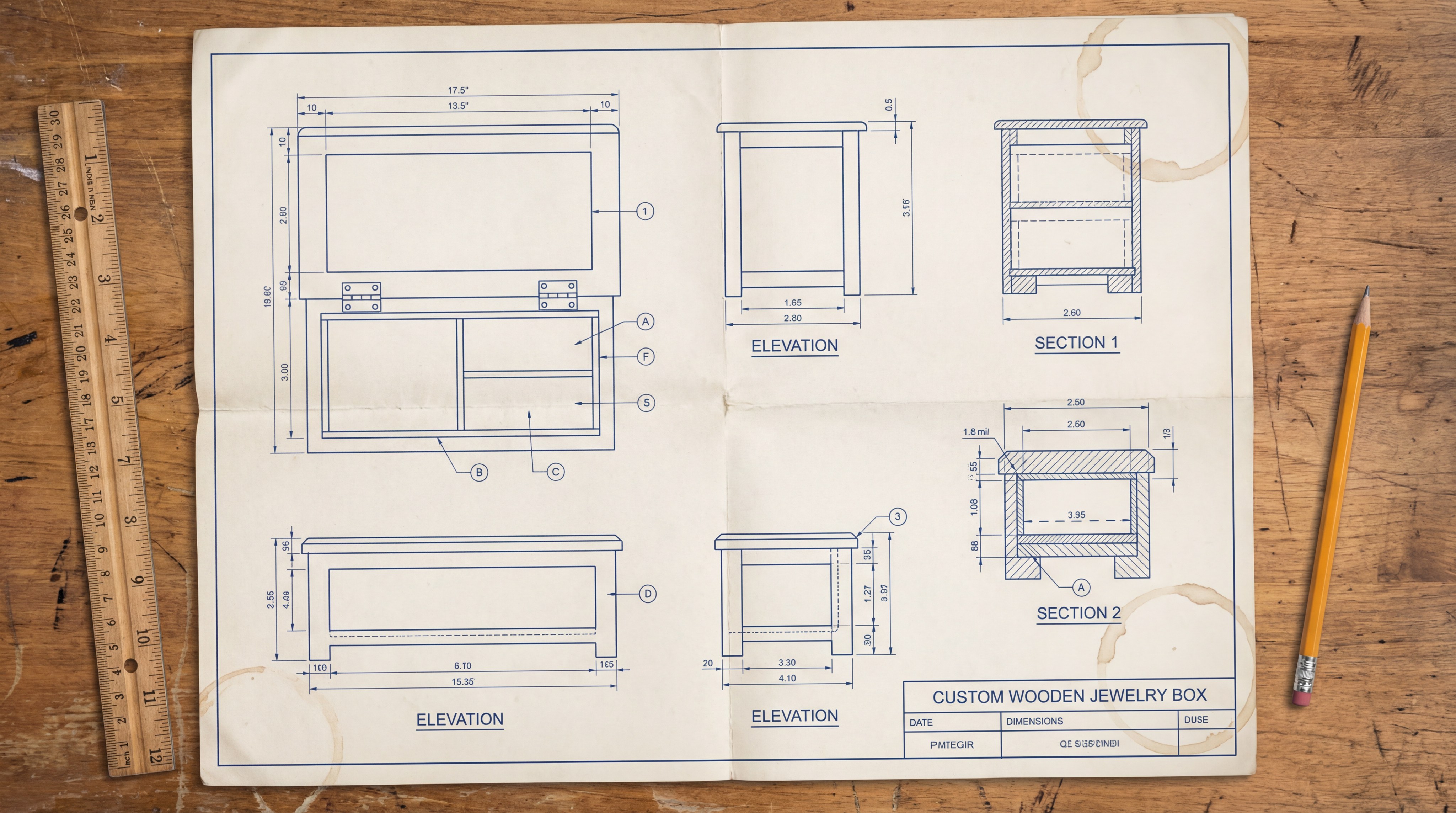

The foundation of any successful woodworking project is a precise plan. A blueprint translates your vision into measurable reality, ensuring that the lid fits perfectly and the drawers slide without friction. Without a technical drawing, you risk wasting expensive hardwoods on miscalculations.

How do dimensions impact utility?

Calculating internal volume is critical for accommodating specific items like chunky necklaces or delicate stud earrings. The depth of the tray must account for the thickness of the lining and the clearance required for the lid to close securely.

| Dimension Component | Importance Level | Primary Function | |

|---|---|---|---|

| Internal Depth | Critical | Prevents jewelry from being crushed by the lid. | |

| Wall Thickness | High | Determines structural integrity and weight. | |

| Tray Clearance | Medium | Ensures smooth removal of modular inserts. |

Which wood species is best for you?

Selecting the right material is a pivotal step when you learn how to make your own jewelry box . Hardwoods like Walnut, Cherry, and Oak are preferred for their stability and grain beauty. The choice of wood dictates the final “feel” of the box—Walnut offers a modern, dark elegance, while Cherry patinas beautifully into a deep reddish-brown over time.

Does grain pattern affect durability?

Straight-grain lumber is easier to work with and less prone to warping than figured or “curly” grain. However, using highly figured wood for the lid panel can create a stunning visual centerpiece that elevates the entire project.

| Wood Type | Workability | Visual Appeal | Best Use | |

|---|---|---|---|---|

| Black Walnut | Excellent | High | Main body and lids. | |

| Hard Maple | Moderate | Clean/Modern | Internal dividers and contrast. | |

| Cherry | Excellent | Classic | Traditional heirloom styles. |

What tools are essential for success?

Precision is the hallmark of jewelry box construction. Unlike larger furniture, small-scale work amplifies even the slightest error. A collection of sharp chisels, a reliable marking gauge, and a fine-tooth Japanese pull saw are the “big three” for creators seeking tight, gap-free joinery.

Are hand tools better than power tools?

While power tools like a table saw provide speed, hand tools offer the finesse required for delicate components. Using a hand plane to “whisper” off a few thousandths of an inch can make the difference between a lid that drops and one that glides into place.

| Tool Type | Essential For | Skill Level | |

|---|---|---|---|

| Marking Gauge | Accurate layout lines | Beginner | |

| Sharp Chisel | Cleaning out joints | Intermediate | |

| Block Plane | Final fitting and chamfers | Intermediate |

How do you ensure workshop safety?

Safety is the most overlooked aspect when researching howto make your own jewelry box . Fine dust from exotic hardwoods can be a respiratory irritant, and the small pieces used in box making often bring fingers closer to blades than in general cabinetry. Protective gear is not optional; it is the barrier between a successful hobby and a life-changing injury.

What protection is non-negotiable?

Eye protection should be worn at all times to guard against flying splinters. Hearing protection is vital for long sessions with routers or sanders, and a high-quality N95 or P100 respirator is essential when sanding fine-grained hardwoods.

| Safety Item | Primary Threat | Usage Frequency | |

|---|---|---|---|

| Safety Glasses | Impact/Splinters | 100% of the time. | |

| Dust Mask | Respiratory damage | During sawing and sanding. | |

| Push Sticks | Finger lacerations | Every table saw cut. |

What are the stages of assembly?

A systematic approach prevents the “glue-up panic” where parts don’t align before the adhesive sets. The process typically moves from dimensioning stock to cutting joints, followed by a dry-fit (assembly without glue) to ensure everything is perfect. Only after a successful dry-fit should you proceed to final glue-up and finishing.

Why is sequence critical in build?

Sanding the internal faces of the box before assembly is a professional secret. Once the box is glued together, reaching into tight corners with sandpaper is nearly impossible and often results in uneven surfaces.

| Phase | Key Activity | Goal | |

|---|---|---|---|

| Milling | Squaring the wood | Perfectly flat stock. | |

| Joinery | Cutting the corners | Structural strength. | |

| Dry-Fit | Testing the assembly | Verification of fit. |

How do you achieve perfect joints?

The miter joint is the standard for jewelry boxes because it conceals the end grain, providing a continuous flow of wood figure around the corners. Achieving a gap-free 45-degree angle is a milestone in discovering how to make your own jewelry box . Clamping pressure must be even to prevent the joint from “walking” or opening up.

Does glue choice matter for miters?

Standard PVA wood glue is effective, but it can be slippery. Using a miter-specific clamp or “blue tape” method can help keep the pieces aligned. For dark woods like walnut, a dyed glue can help hide the thin glue line at the seam.

| Joint Type | Difficulty | Aesthetic Value | |

|---|---|---|---|

| Miter | Moderate | High (Clean lines). | |

| Dovetail | High | Very High (Traditional). | |

| Splined Miter | Moderate | High (Adds contrast). |

Which hardware adds the most value?

High-quality hardware is the “jewelry” of the jewelry box. Solid brass hinges and locks not only look better than plated steel but also provide a mechanical smoothness that cheaper alternatives lack. The weight and resistance of the hinge contribute significantly to the perceived quality of the final piece.

Are quadrant hinges worth the cost?

Quadrant hinges are the gold standard for luxury boxes. They provide a built-in “stop” that holds the lid open at 95 degrees, and they are mortised into the wood for a flush, professional appearance. While difficult to install, their elegance is unmatched.

| Hardware Item | Material Choice | Benefit | |

|---|---|---|---|

| Butt Hinge | Solid Brass | Classic, reliable. | |

| Quadrant Hinge | Polished Brass | Luxury look, built-in stop. | |

| Escutcheon | Inlaid Brass | Protects the lock hole. |

How do you apply a velvet lining?

Lining the interior is the final functional step in learning how to make your own jewelry box . Velvet or microsuede protects gemstones from scratches and creates a luxurious backdrop. The key to a professional lining is using a stiff backing—like heavy cardstock—to which the fabric is glued before being inserted into the box.

What adhesive works best for fabric?

A specialized spray adhesive or a thin layer of white glue is best. Avoid using too much glue, as it can “bleed” through the fabric, creating unsightly stiff spots on the velvet surface.

| Lining Material | Durability | Luxury Feel | |

|---|---|---|---|

| Silk Velvet | Moderate | Maximum. | |

| Synthetic Suede | High | Moderate. | |

| Flocking | Low | High (seamless). |

What finishing touches create an heirloom?

The finish protects the wood from moisture and skin oils while highlighting the natural beauty of the grain. A “close-to-the-wood” finish, like a hand-rubbed oil and wax, provides a tactile experience that invites people to touch the box. High-gloss lacquers are durable but can sometimes feel plasticky on small items.

How many coats of oil are enough?

For a jewelry box, three to five thin coats of a drying oil (like Tung oil or Danish oil) are usually sufficient. Each coat should be sanded lightly with high-grit sandpaper to achieve a glass-smooth surface.

| Finish Type | Application | Appearance | |

|---|---|---|---|

| Danish Oil | Wipe-on | Satin/Natural. | |

| Shellac | Brush/Pad | Classic/Warm. | |

| Polyurethane | Wipe/Spray | Highly Durable. |

How do you personalize the final piece?

The final stage of knowing how to make your own jewelry box is adding a personal signature. Whether it’s an engraved name, a special date, or a hidden compartment, these details transform a “project” into a “treasure.” Personalization ensures the box is cherished as much for the person who made it as for the jewelry it holds.

Is laser engraving better than hand?

Laser engraving offers incredible precision for complex logos or script fonts. Hand-carving, while more time-consuming and requiring a higher skill level, offers a unique “human” touch that machines cannot replicate.

| Personalization | Tool Required | Sentiment Level | |

|---|---|---|---|

| Laser Engraving | CNC/Laser | High. | |

| Hand Carving | Gouges/Chisels | Very High. | |

| Wood Inlay | Router/Knife | High. |