Expert manufacturing firms like YX Jewelry Packaging are the primary answer for those wondering who produces jewelry with standout packaging? Many high-end brands struggle because their exquisite collections are often delivered in generic containers that diminish the perceived value of the craft. This lack of distinction creates a disconnect between the luxury of the jewelry and the physical experience of the customer. Choosing a specialist partner ensures your brand identity is preserved and elevated through every tactile detail.

Key Takeaways

- Structural integrity is the foundation of luxury packaging in 2026.

- Material selection must balance tactile premium feel with modern sustainability.

- Bespoke inserts are essential for protecting high-value gems during transit.

- The unboxing experience is a vital tool for organic social media growth.

Who produces jewelry with standout packaging?

Specialist manufacturers with dedicated design teams are the ones who produces jewelry with standout packaging? for the world’s most prestigious labels. These firms focus on the intersection of structural engineering and aesthetic beauty. They provide the technical expertise required to transform a simple container into a brand ambassador.

Does custom design drive brand recognition?

The truth is, your packaging is often the first physical touchpoint a customer has with your brand. Consistent use of logos, specific color palettes, and unique opening mechanisms creates an instant association with your luxury status.

- Custom embossed logos

- Signature brand colors

- Unique box geometries

- Proprietary opening styles

What role does expert manufacturing play?

Think about it: a beautiful design fails if the execution lacks precision or durability. Expert manufacturers utilize high-density materials and advanced printing techniques to ensure every edge is sharp and every closure is secure.

Key TakeawayQuality manufacturing ensures that the physical box reflects the meticulous care you put into your jewelry pieces.

| Feature | Impact | |

|---|---|---|

| Precision Die-Cutting | Crisp edges and perfect fit | |

| Custom Printing | Vibrant, consistent brand colors | |

| High-Density Board | Premium weight and durability |

What defines high-end jewelry box quality?

Material density, finishing techniques, and internal security are the core elements that answer who produces jewelry with standout packaging? when assessing quality. A high-end box must feel substantial in the hand and offer a smooth, silent operation. Premium branding is defined by these small, sensory details that generic suppliers often overlook.

Is structural durability a luxury standard?

Here is the deal: a box that warps or collapses instantly signals a low-quality product to your customer. Luxury standards require reinforced corners and heavy-duty chipboard that maintains its shape for years.

- Reinforced internal frames

- Warp-resistant materials

- Heavy-gauge chipboard

- Precision-fit lids

Why does interior lining matter for gems?

Look, the lining is what directly interacts with your most valuable assets, from diamonds to delicate pearls. Using anti-tarnish fabrics and high-grade velvet prevents chemical reactions and physical abrasions.

Key TakeawayThe interior of your packaging must be as functional as the exterior is beautiful to protect your brand reputation.

| Lining Type | Primary Benefit | |

|---|---|---|

| Anti-Tarnish Velvet | Prevents metal oxidation | |

| High-Grade Silk | Ultra-soft surface for pearls | |

| Microfiber | Scuff-free protection for polished gold |

How to choose the right packaging partner?

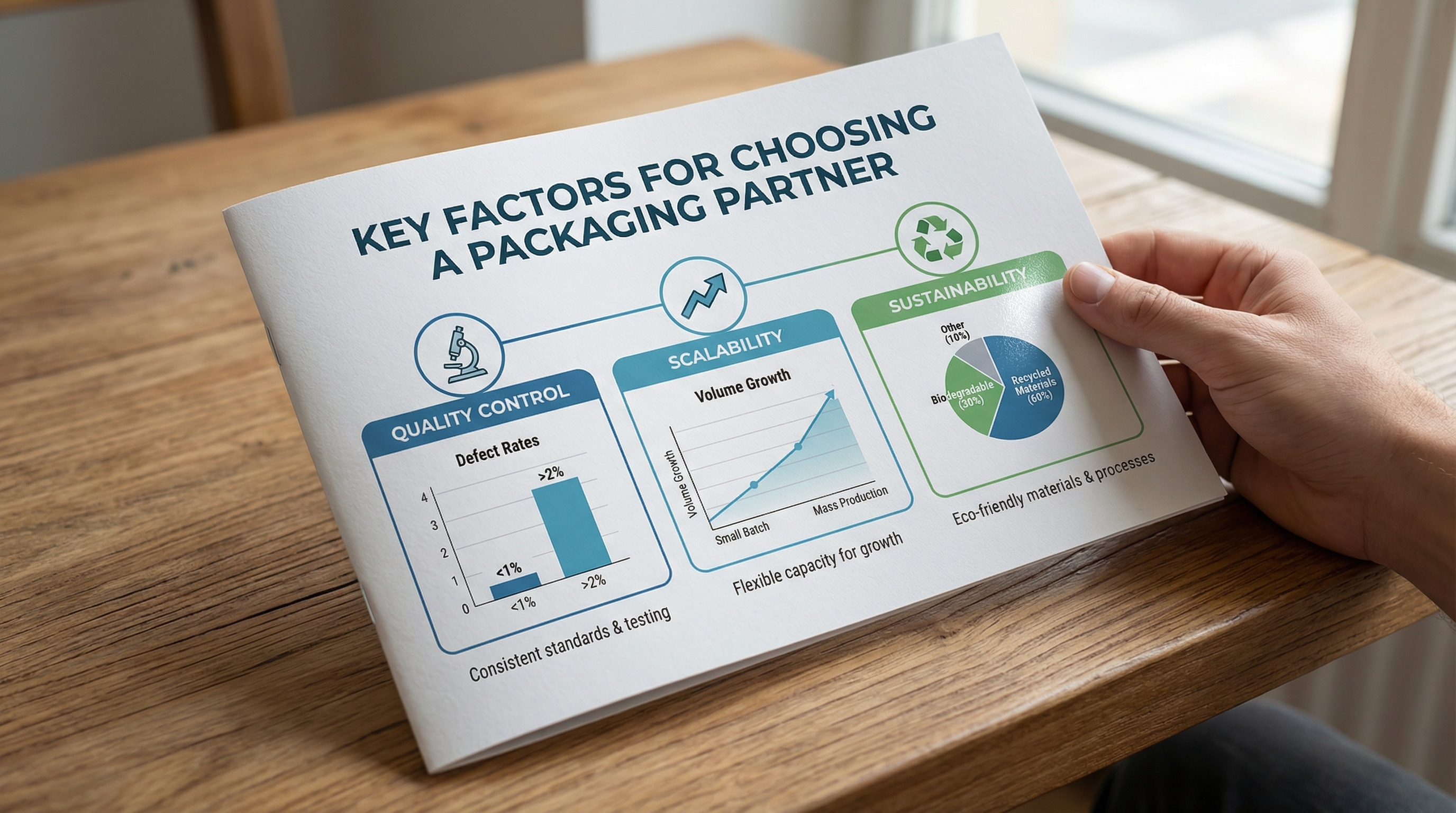

Reliable firms who produces jewelry with standout packaging? should be evaluated based on their prototyping speed and their ability to scale production without losing quality. You need a partner that understands the nuances of the jewelry industry, rather than a generalist printer. Verification of their quality control processes is non-negotiable for high-end branding.

Do they offer rapid prototyping services?

Believe it or not, seeing a physical sample is the only way to truly judge the tactile quality of a design. Rapid prototyping allows you to test closures and material feel before committing to a large order.

- Physical 3D mockups

- Material swatch books

- Digital structural templates

- Finishing effect samples

Can they handle high-volume scalability?

The reality is that your packaging partner must be able to grow alongside your brand’s success. Scalability ensures that as your order volume increases, the unit price becomes more efficient while the quality remains identical to the first batch.

Key TakeawayA partner that scales with you prevents supply chain disruptions during peak seasons or major collection launches.

| Service Metric | Optimal Standard | |

|---|---|---|

| Prototyping Lead Time | 7-10 Days | |

| Bulk Production | 25-35 Days | |

| Quality Check Ratio | 100% Manual Inspection |

Why is the unboxing experience critical?

Creating an emotional connection through the unboxing process is how brands determine who produces jewelry with standout packaging? in the digital age. A well-designed unboxing experience turns a customer into a brand advocate who is likely to share their purchase online. Every layer of the package should build anticipation for the jewelry piece inside.

Does packaging influence social sharing?

But here’s the kicker: jewelry is one of the most shared categories on social media, provided the presentation is aesthetic. Elegant ribbons, wax seals, and textured papers encourage customers to film “unboxing” videos that provide free marketing.

- Aesthetic layering

- Instagrammable textures

- Branded tissue paper

- Personalized thank-you notes

How do magnetic closures enhance prestige?

Think about it: the sound and feel of a magnetic closure snapping shut provides a psychological sense of security and value. It removes the clunkiness of traditional hinges and offers a sleek, modern profile.

Key TakeawayThe sensory details of the opening process are just as important as the visual design for luxury perception.

| Sensory Element | Brand Perception | |

|---|---|---|

| Magnetic Snap | Security and high-tech precision | |

| Textured Paper | Hand-crafted luxury feel | |

| Scented Linings | Memorable emotional connection |

Which materials are trending for 2026?

Sustainable luxury and hybrid metallic finishes are the top trends for who produces jewelry with standout packaging? in the upcoming year. Brands are moving away from plastics and toward biodegradable resins and FSC-certified papers. These materials prove that environmental responsibility does not have to come at the expense of a premium aesthetic.

Is eco-friendly luxury finally achievable?

The truth is, modern paper technology now allows for recycled materials that feel as soft as suede or as smooth as silk. Consumers in 2026 demand sustainability, and providing it elevates your brand’s ethical standing.

- FSC-certified wood pulp

- Mushroom-based inserts

- Soy-based metallic inks

- Recycled ocean plastic accents

Are metallic textures making a comeback?

Make no mistake, gold and silver foil stamping remain the gold standard for high-end branding. New techniques allow for “brushed” metallic textures on paper that provide a futuristic yet timeless look.

Key TakeawayIntegrating eco-friendly materials with high-end finishes is the most effective way to modernize your brand image.

| Material Trend | 2026 Application | |

|---|---|---|

| Bio-Resin Cases | Sustainable alternative to plastic | |

| Brushed Foil | Sophisticated metallic branding | |

| Vegan Leather | Ethical luxury exterior |

How do custom necklace boxes add value?

Providing specialized protection for delicate chains is a hallmark of who produces jewelry with standout packaging? for luxury retailers. When you utilize premium necklace boxes , you ensure that the presentation remains pristine from the vault to the customer’s home. These boxes are designed to highlight the drape and sparkle of the piece.

Can specialized inserts prevent tangling?

It gets better: there is nothing more frustrating for a customer than receiving a high-value necklace that has become a knotted mess during shipping. Custom inserts with multi-point hooks and padded backings keep chains taut and secure.

- Multi-hook tension systems

- Padded velvet backboards

- Recessed pendant slots

- Integrated cleaning cloth storage

What impact does box height have on display?

The deal is that different necklace styles require specific box depths to prevent the lid from crushing delicate stones. Tall boxes provide the necessary clearance for large statement pieces or multi-strand designs.

Key TakeawayFunctional necklace packaging prevents damage and ensures a perfect presentation every time the box is opened.

| Box Style | Best For | |

|---|---|---|

| Slim Profile | Delicate chains and chokers | |

| Deep Showcase | Statement pendants and pearls | |

| Fold-Out Tray | Multi-piece jewelry sets |

Why invest in specialized bracelet boxes?

Customization for wristwear is a key differentiator for brands who produces jewelry with standout packaging? in competitive markets. Using bespoke bracelet boxes allows you to choose between flat lay designs and curved watch-style pillows. This choice depends entirely on the flexibility and style of the bracelet collection.

Should you choose flat or curved designs?

Bottom line: flat boxes are ideal for rigid bangles, while curved pillows are essential for soft-link bracelets to maintain their shape. A pillow display makes the bracelet look “worn” even while it is in the box.

- C-ring inserts for bangles

- Plush pillows for link bracelets

- Elasticated corner tabs

- Recessed centers for charms

How does shipping protection vary for bracelets?

Believe it or not, bracelets are prone to sliding within a box, which can lead to surface scratches. Custom-fitted inserts eliminate movement, ensuring the piece remains centered during international transit.

Key TakeawayTailoring the internal structure to the specific flexibility of your bracelet ensures both safety and style.

| Insert Type | Ideal Bracelet Style | |

|---|---|---|

| C-Clip | Rigid bangles and cuffs | |

| Center Pillow | Tennis bracelets and chains | |

| Flat Recess | Delicate charm bracelets |

What makes a ring box feel premium?

The tactile “click” and the softness of the exterior finish are the defining factors for who produces jewelry with standout packaging? in the ring sector. When customers browse high-end ring boxes , they look for a compact yet sturdy design that feels significant. For proposals or high-value gifts, the box is an integral part of the emotional moment.

Is a soft-touch finish worth the cost?

The reality is that a soft-touch coating provides an immediate sense of luxury that standard gloss or matte finishes cannot match. It invites the customer to touch the box, creating a positive sensory experience before the jewelry is even seen.

- Velvet-flocked exteriors

- Rubberized soft-touch coatings

- Premium vegan leather wraps

- High-gloss piano lacquer

How do LED inserts change the presentation?

Look, in low-light environments like a romantic dinner, a small integrated LED can make a diamond’s fire pop. This technological integration is a growing trend for high-end engagement ring branding.

Key TakeawaySmall details like soft-touch finishes and lighting can significantly increase the perceived value of the ring inside.

| Feature | Psychological Effect | |

|---|---|---|

| Integrated LED | Highlights diamond clarity | |

| Weighted Base | Signals high-end material quality | |

| Hidden Hinge | Creates a seamless, modern look |

Are earring boxes essential for branding?

The versatility to display various styles is why firms who produces jewelry with standout packaging? focus heavily on modular earring inserts. Utilizing wholesale earring boxes with interchangeable cards allows a brand to maintain a consistent outer look while accommodating different jewelry sizes. This efficiency is vital for maintaining a cohesive brand image across a large catalog.

How to display studs versus drop designs?

But here’s the kicker: a single hole in an insert isn’t enough for a professional brand. You need varied slit and hole configurations to ensure that heavy drops don’t sag and tiny studs don’t get lost.

- Dual-slit cards for drops

- Precision-drilled stud holes

- Angled display inserts

- Anti-tarnish protective flaps

Why is vertical presentation becoming popular?

Think about it: vertical displays in a box allow the jewelry to catch the light more effectively than a flat layout. It mimics the way jewelry is shown in high-end retail boutiques.

Key TakeawayFlexible earring packaging allows your brand to present a diverse collection within a unified packaging system.

| Display Style | Advantage | |

|---|---|---|

| Vertical Card | Better light reflection | |

| Flat Lay | Safer for long, delicate drops | |

| Multi-Pair Slot | Perfect for curated sets |

Why do luxury watches need custom cases?

Weight and internal cushioning are the primary concerns for who produces jewelry with standout packaging? for the horological market. When you invest in luxury watch boxes , the primary goal is to protect a heavy, mechanical instrument from shock. A watch box must feel as engineered and precise as the timepiece it contains.

Can custom pillows prevent movement?

Make no mistake, a loose watch in a box will eventually sustain damage to its movement or bracelet. Custom-sized pillows that fit snugly within the compartment are the only way to ensure the watch remains stationary.

- High-density foam cores

- Adjustable pillow widths

- Microfiber exterior wraps

- Elasticated security straps

What role does the outer “sleeve” play?

The truth is, an outer sleeve or “packer” box provides an extra layer of protection during shipping and a sense of “prestige” during the reveal. It keeps the main luxury box free from dust and fingerprints.

Key TakeawayWatch packaging must prioritize mechanical protection and heavy-duty construction to match the product’s value.

| Component | Function | |

|---|---|---|

| Weighted Core | Prevents tipping and signals luxury | |

| Oversized Pillow | Maintains bracelet shape and tension | |

| Outer Sleeve | Protects the primary box finish |

Future-Proofing Your Brand

As the jewelry market evolves in 2026, the transition toward personalized and technologically integrated packaging will separate industry leaders from followers. Your brand vision should include a physical presentation that is as innovative and sustainable as the jewelry you create. By focusing on tactile quality, environmental responsibility, and structural precision, you ensure your brand remains relevant and desired.

Ready to elevate your jewelry brand’s physical presence? Contact us today to start designing your standout packaging solution.

FAQ

Can I order custom samples before a full production run?Yes, most high-end firms provide physical prototypes to ensure the dimensions, materials, and branding meet your exact specifications before bulk manufacturing.

What’s the best material for eco-friendly luxury boxes?FSC-certified papers and biodegradable bio-resins are currently the gold standard, offering a premium feel without the environmental impact of traditional plastics.

How do I prevent my necklaces from tangling during shipping?Utilizing custom inserts with tension hooks and padded backboards is the most effective way to keep delicate chains secure and tangle-free.

Can I integrate technology like LEDs into my ring boxes?Yes, integrated LED lighting is a popular custom feature that enhances the sparkle of gemstones, especially for engagement and proposal-style packaging.

What is the standard lead time for custom jewelry packaging?Generally, you should expect 7 to 10 days for prototyping and 25 to 35 days for bulk production, depending on the complexity of your custom design.