Wholesale Jewelry Boxes: How We Consolidated a Fragmented Supply Chain for a Top Distributor

Discover how we helped a client managing 500+ retail points optimize their bulk packaging logistics, reducing reject rates by 95% and cutting landed costs through standardized wholesale solutions.

Scale your business with factory-direct efficiency.

The Context: A Supply Chain in Crisis

Before partnering with YiXin, the client was juggling three different factories. This fragmentation led to mixed color batches, a 15% rejection rate, and chaotic inventory management that threatened their Q4 distribution.

- Handling 300+ SKU variations with non-modular boxes.

- Inconsistent "Brand Gold" color across different batches.

- Unit costs rising by 8% annually due to poor planning.

- Pallets arriving with crushed bottom-layer cartons.

- High warehouse labor costs for sorting mixed SKUs.

Do these struggles sound familiar to your operations?

See What Capability You NeedSpecific Challenges They Faced

These were the tangible operational failures that were eroding the client's profit margin before our intervention.

Inconsistent Brand Colors

Batch A (March) was visibly darker than Batch B (June), confusing retailers and damaging brand image.

SKU Mismatch

Loose-fitting ring packaging proved too wide for their new thinner band collection, causing product rattle and damage.

Inventory Turnover Stagnation

Ordered 50k units of a non-standard size that sat in the warehouse for 18 months, tying up $20,000 in cash flow.

Missed Deadlines

Previous supplier delayed the critical Christmas shipment by 2 weeks, missing the shelf date.

Crushed Cartons

Using weak single-wall cartons caused a 12% damage rate on sea freight shipments.

No QC Reports

Goods arrived without any inspection data, forcing the client to manually check every box.

These issues are common in bulk packaging operations.

View Our Engineered SolutionThe Real Cost: How It Flowed Downstream

The client realized that a simple "box problem" was actually a supply chain disaster waiting to happen.

15% Return Rate

Product Damage

Sorting Bottlenecks

Inflated Logistics

Poor packaging affects profitability and partner confidence.

See Verified Improvement DataThe Capability Gap: What They Lacked

They didn't just need boxes; they needed an on-the-ground engineering team to standardize specs across all SKUs.

On-Site QC Team

They lacked a team in China to reject bad batches before shipping.

Engineering Support

They needed structure design to make one box fit 5 different rings.

Production Planning

They needed a plan that matched their sales curve, not factory minimums.

Logistics Optimization

They needed cartons optimized for pallet efficiency to cut freight bills.

Successful wholesale packaging must meet all these demands.

Continue to Our SolutionHow YiXin Intervened & Executed

We deployed a dedicated project team to redesign their packaging ecosystem, consolidating production to our central facility to ensure 100% consistency.

Centralized Production

Moved all 300 SKUs to our facility, ensuring uniform material sourcing and color matching.

Modular Engineering

Designed universal multi-sku inserts that reduced box types from 50 to 12, simplifying inventory.

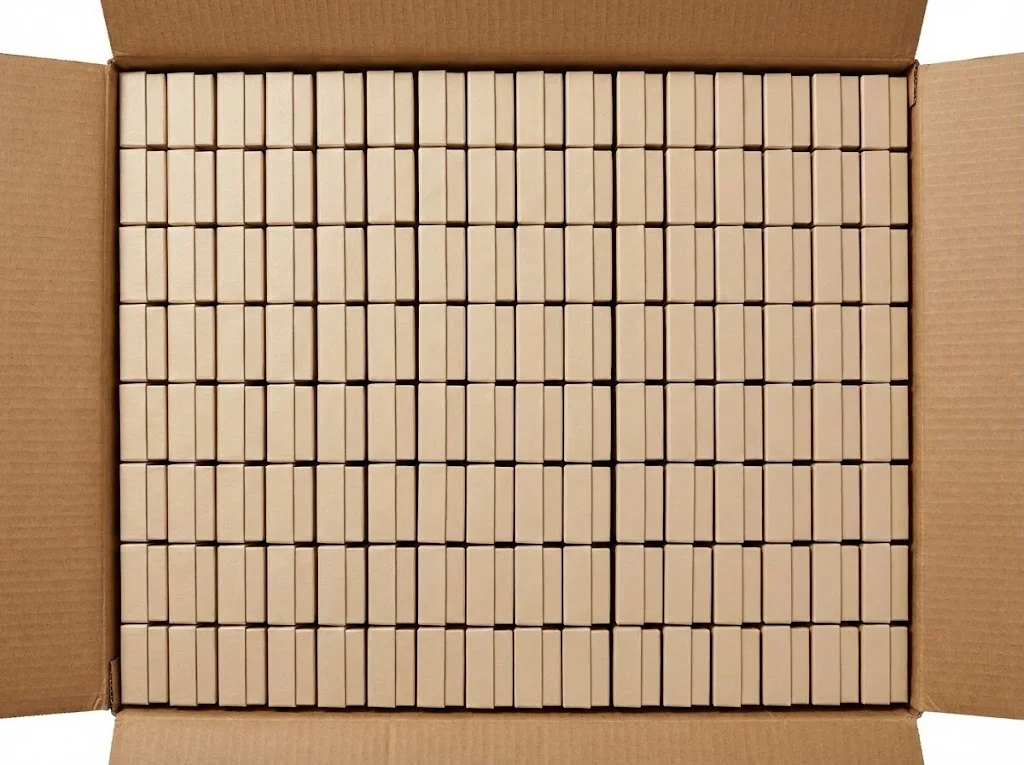

Pallet Optimization

Re-engineered outer cartons to fit perfectly on standard EU pallets (1200x800mm), achieving 98% container space utilization.

This solution is built for bulk and scalable needs.

View Our Wholesale Packaging SolutionWant This Exact Solution?

The modular rigid box system used in this case is available for customization. MOQ starts at 1,000 units.

Project Results: Before vs After

The numbers speak for themselves. Here is the verified data from the first 6 months of our partnership.

Before Optimization

- Defect Rate 5.2% (Avg)

- Logistics Cost High (Volumetric)

- Inventory Speed Slow / Manual

- Customer Returns Frequent Complaints

After YiXin Intervention

- Defect Rate 0.3% (Verified)

- Logistics Cost -22% Optimized

- Order Fulfillment Speed 2x Faster Sorting

- Customer Returns Rare (<0.1%)

Visual proof of packaging performance improvements.

Get Similar Results NowScope of Project Delivery

For this distributor, we provided a complete suite of solutions covering their entire logistics chain, from bulk transit to retail display.

50k Unit Bulk Pallets

High-density packing solution delivered monthly.

Universal Insert System

One insert designed to hold 5 different jewelry types.

Reinforced Master Cartons

Double-wall protection for inter-hub transport.

Retail-Ready Barcoding

Pre-applied labels for immediate shelf stocking.

Different wholesale challenges need tailored packaging.

See All Packaging ProductsExecution Risks We Mitigated

During this project, we identified and neutralized several critical risks that could have derailed the entire distribution timeline.

Material Downgrade Risk

We ensured the factory didn't swap paper weight mid-production, a common cause of crushed boxes in bulk orders.

Color Deviation

We implemented a "Golden Sample" protocol at the printing press to stop any color shift before mass printing began.

Fit Tolerance

We caught a 2mm mold error during the pre-production sample phase, saving 50,000 units from being scrapped.

Pallet Overhang

We resized the master carton by 1cm to ensure zero overhang on EU pallets, preventing transit damage fines.

Knowing pitfalls helps you save time and money.

View Pitfall-Free PackagingWe’ve Solved This for Them. Now Let’s Solve It for You.

You’ve seen the data. We have the proven engineering capability and logistics network to stabilize your supply chain immediately.

- 95% Reject Rate Reduction (Proven)

- Guaranteed Color Consistency

- 20%+ Logistics Savings

- Rapid Prototype Validation

- Dedicated Account Manager Support

Start Your Optimization

Contact us to replicate this success for your brand.