Core Structure: Plastic vs. Cardboard

The structural foundation is critical for Custom Ring Boxes Wholesale. Unlike general packaging, a ring box needs a mechanical "snap" closure. We strongly recommend a Plastic Hinged Core for high-end engagement rings. It provides that satisfying "click" sound and 90-degree opening angle.

Cardboard cores are lighter and cheaper, suitable for jewelry sets but lack the mechanical durability of plastic. (See our Luxury Brand Case for material comparisons).

- Plastic Core: Best for velvet/leather wrapping; ensures a tight hinge snap.

- Cardboard Core: Eco-friendly, lightweight, best for lid-off or drawer styles.

Mastering Inner Lid Branding

As a specialized Ring Box Manufacturer, we know the most valuable real estate is the Inner Lid. This is what the customer sees immediately above the diamond when the box is opened.

Hot Stamping (Foil) in Gold or Silver is the industry standard for the inner satin or velvet lining. For Retail Chains requiring high-frequency usage, this durability is key. (Check Retail Display Standards).

The Importance of the "H-Slot" Insert

A loose ring is a disaster. Our Custom Ring Inserts feature a precision-cut "H-slot" or "I-slot" capable of holding bands ranging from 2mm to 8mm securely.

Proper inserts are crucial for reducing returns for Online Jewelry Sellers. We use high-density sponge topped with premium plush velvet to ensure the ring stands upright at a 90-degree angle for the best display impact.

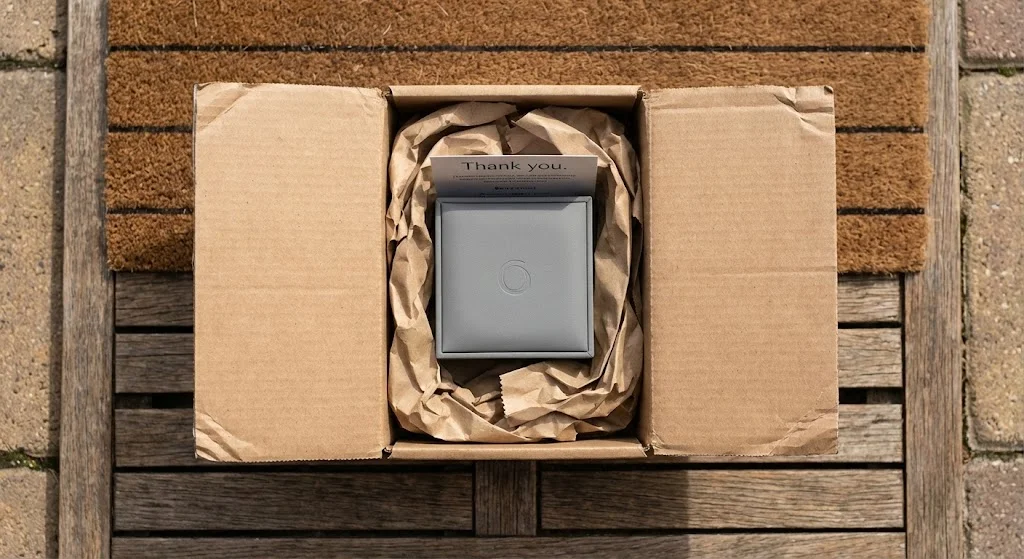

Logistics: Shipping Dense Cargo

When importing Bulk Ring Boxes, note that they are small but dense. Unlike large paper bags, ring boxes often hit their actual weight limit before their volumetric weight limit.

For Wholesalers, we recommend Sea Freight for orders over 5,000 pcs to maximize ROI. We use reinforced 5-ply outer cartons to prevent crushing during transit.