In the luxury retail sector, the unboxing experience is often the first tangible touchpoint between your brand and the consumer. If a customer opens a high-end package only to find tangled chains or shifted gemstones, the perceived value of the purchase plummets instantly. Understanding how to make jewelry box inserts is not merely a DIY skill; it is a critical B2B competency that ensures product safety and professional branding. By investing in bespoke organization, such as our specialized Custom Ring Boxes , you transform standard storage into a sophisticated asset protection system.

What materials are best for how to make jewelry box inserts?

You should select materials that offer a balance between structural rigidity and surface softness to prevent abrasions. When researching how to make jewelry box inserts, industry leaders typically prioritize high-density EVA foam or rigid paperboard lined with premium velvet. These materials provide the necessary “grip” to keep items like those in Custom Earring Boxes secure during international transit.

Why is EVA foam preferred for B2B applications?

High-density EVA foam is the gold standard for bulk manufacturing because it can be precisely die-cut to any silhouette. It offers superior shock absorption, which is vital for protecting heavy or fragile gemstones from impact during handling.

How does velvet lining enhance product value?

Velvet provides a high-friction surface that prevents jewelry from sliding, while its luxurious sheen creates a premium backdrop for gold and diamonds. It also acts as a gentle buffer against oxidation by reducing the air pockets around the metal.

Think about this: The material you choose is the foundation of your brand’s physical reputation.

- High-density EVA foam for impact protection.

- Premium velvet or suede for scratch resistance.

- Rigid chipboard for lightweight structural support.

- Anti-tarnish fabrics for long-term inventory storage.

Key Takeaway: Professional inserts require high-performance substrates like EVA foam paired with luxury textiles to ensure both safety and aesthetic appeal.

| Material | Primary Benefit | Best Suited For | |

|---|---|---|---|

| EVA Foam | Maximum Shock Absorption | Heavy or fragile luxury items | |

| Velvet | Scratch Prevention | High-polish metals and gems | |

| Rigid Card | Cost-Effective Bulk | Lightweight retail sets |

How do you measure for how to make jewelry box inserts?

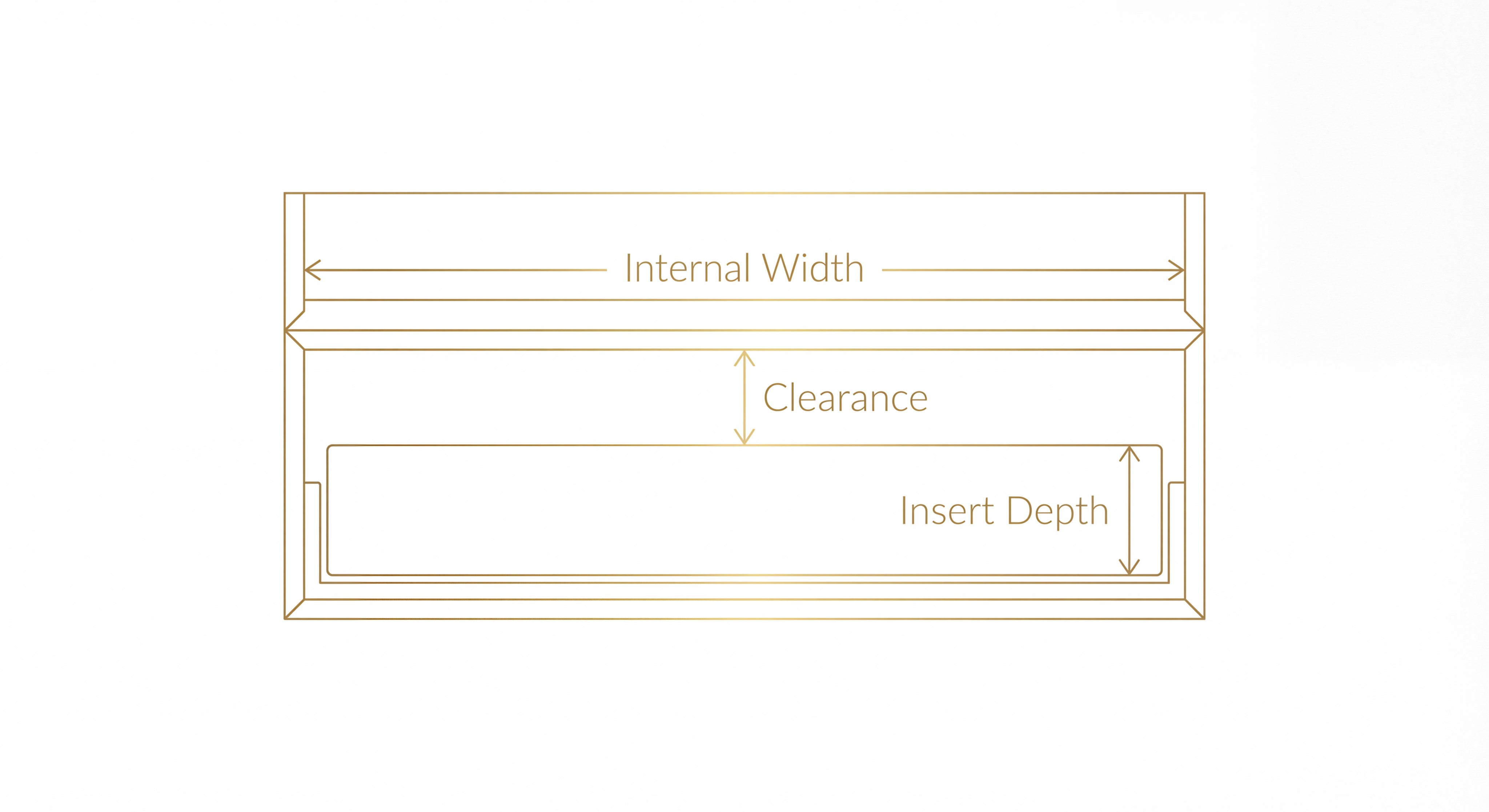

You must use digital calipers to record the internal “clear” dimensions of your box, accounting for wall thickness and lid clearance. Precise measurement is the most critical step in learning how to make jewelry box inserts, as even a 1mm error can result in a loose fit that compromises protection. Ensuring a “friction-fit” means the insert should stay in place without the need for messy adhesives.

What is the difference between external and internal dimensions?

External dimensions are for shipping logistics, while internal dimensions dictate the exact footprint available for your jewelry tray. You must subtract the thickness of the box walls (usually 1.5mm to 3mm) from the outer measurements to get your working area.

How do you account for fabric tolerances?

When you wrap foam or board in velvet, the fabric adds roughly 0.5mm to 1mm of thickness to every edge. Professional designers always deduct this “fabric allowance” from the base insert size to ensure the final piece slides in smoothly.

It gets better: Precision in the planning phase saves thousands of dollars in wasted materials during mass production.

- Measure the internal width and length at the base.

- Calculate the height required to clear the closed lid.

- Determine the depth of the jewelry cavities based on product height.

- Subtract 1mm for fabric wrapping tolerances.

Key Takeaway: Accurate measurement using professional tools prevents the “shifting” of inventory and ensures a seamless, high-end look for the finished package.

| Measurement Type | Tool Required | Critical Factor | |

|---|---|---|---|

| Base Dimensions | Digital Caliper | Accounting for wall thickness | |

| Lid Clearance | Depth Gauge | Avoiding pressure on the jewelry | |

| Cavity Depth | Steel Ruler | Ensuring the piece sits flush |

What is the process for how to make jewelry box inserts for rings?

You create ring inserts by compressing velvet-wrapped foam rolls into a rigid frame to create secure tension slots. This method for how to make jewelry box inserts ensures that bands of varying widths stay upright and centered during unboxing. For modern, minimalist displays, you might also consider a PE Film Jewelry Box which offers a unique 3D floating effect.

How do you achieve the perfect tension in ring rolls?

The diameter of your foam rolls should be slightly larger than the space they occupy within the frame. This compression creates the “grip” necessary to hold a heavy platinum band without it leaning or falling over.

What adhesives are safe for fine jewelry?

When bonding fabric to foam, you must use pH-neutral, acid-free adhesives to prevent chemical reactions that cause silver and gold to tarnish. Spray adhesives are generally preferred for their even distribution and lack of “bleed-through” on delicate fabrics.

Believe it or not: A well-tensioned ring insert can withstand a 3-foot drop without the jewelry dislodging.

- Cut foam cylinders to the internal width of the box.

- Wrap each cylinder tightly in acid-free velvet.

- Apply a thin layer of pH-neutral glue to the frame base.

- Press the rolls together firmly to eliminate gaps.

Key Takeaway: Ring rolls rely on lateral compression to secure jewelry, making the choice of foam density and fabric grip essential for long-term stability.

| Insert Component | Material Specification | Purpose | |

|---|---|---|---|

| Core Roll | Medium-Density Foam | Provides the necessary compression | |

| Lining | Micro-Velvet | Grips the ring band securely | |

| Base Frame | 1200gsm Chipboard | Keeps rolls aligned and square |

How to make jewelry box inserts for necklace stability?

You must design angled notches or recessed cavities to prevent chains from tangling or sliding behind the insert. Learning how to make jewelry box inserts for necklaces requires a focus on “tension-backing,” where the excess chain is hidden and secured at the rear. This professional approach is standard in high-volume Custom Necklace Boxes to maintain a pristine presentation.

Where is the best placement for necklace notches?

Notches should be placed in the upper third of the insert, angled slightly toward the center to guide the chain downward. This positioning ensures the pendant remains the focal point while the chain follows a natural, aesthetic curve.

How do you handle heavy pendants?

For substantial pieces, you should die-cut a custom cavity in the foam base that matches the pendant’s shape. This prevents the weight of the stone from pulling the chain through the notches and causing the item to sag.

Here is the kicker: A necklace that stays in place is a necklace that sells itself at first sight.

- Angle notches at 45 degrees for maximum grip.

- Use a rear “pocket” to store excess chain length.

- Incorporate a soft pad behind the notches to prevent metal-on-metal friction.

- Ensure the pendant cavity is 2mm deeper than the stone.

Key Takeaway: Necklace inserts must manage both the visual display of the pendant and the functional storage of the chain to prevent damage and tangling.

| Design Element | Function | Retail Benefit | |

|---|---|---|---|

| Angled Notches | Holds chain tension | Prevents shifting during unboxing | |

| Recessed Cavity | Protects the pendant | Reduces impact damage | |

| Rear Pocket | Conceals excess chain | Creates a clean, professional look |

How to make jewelry box inserts for luxury bracelet boxes?

You should utilize C-clips or velvet-lined pillows to maintain the circular shape of rigid bangles and cuffs. When mastering how to make jewelry box inserts for bracelets, you must consider the “drop” of the item so it doesn’t hit the bottom of the box. Our Luxury Bracelet Boxes utilize these tiered supports to provide a three-dimensional display that captures light from all angles.

Should you choose pillows or rigid C-clips?

Pillows are ideal for flexible chain bracelets as they fill the void and prevent the jewelry from collapsing into a pile. C-clips are better for rigid bangles, as they provide a minimalist “floating” look that highlights the metalwork.

How do you secure tennis bracelets?

Tennis bracelets require multiple points of contact, usually provided by small elastic straps or subtle foam tabs. These prevent the heavy diamond settings from rotating or twisting within the box.

The truth is: Customers judge the quality of a bracelet by how securely it is presented in its home.

- Pillow inserts for flexible chain designs.

- Acrylic or foam C-clips for rigid cuffs.

- Elastic stay-tabs for multi-stone tennis bracelets.

- Tiered platforms for stacked bracelet sets.

Key Takeaway: Bracelet inserts must provide internal volume (like a pillow or clip) to ensure the piece maintains its intended shape and catches the light properly.

| Support Method | Ideal Jewelry Type | Visual Style | |

|---|---|---|---|

| Velvet Pillow | Flexible chains/Watches | Traditional Luxury | |

| C-Clip | Rigid Bangles/Cuffs | Modern Minimalist | |

| Elastic Tabs | Tennis Bracelets | High-Security/Functional |

What tech helps you know how to make jewelry box inserts?

You can leverage laser cutting or CNC milling to achieve industrial-grade precision for complex jewelry silhouettes. These technologies are essential when figuring out how to make jewelry box inserts for high-volume B2B orders where consistency is paramount. Automation allows for the creation of intricate internal compartments that would be impossible to cut by hand with the same level of accuracy.

Is laser cutting worth the investment for small brands?

For small batches, laser cutting offers a low barrier to entry because it doesn’t require expensive physical dies. You can simply upload a CAD file and produce 50 to 100 inserts with perfect tolerances in a matter of hours.

How does die-cutting compare for large-scale production?

Die-cutting is significantly more cost-effective for runs of 1,000 units or more. Once the steel-rule die is manufactured, the per-unit cost of the insert drops substantially, making it the preferred choice for major retail launches.

Make no mistake: The right technology determines whether your packaging looks artisanal or amateur.

- CAD software for initial design and testing.

- Laser cutters for prototyping and small batches.

- Die-cutting machines for high-volume retail.

- CNC routers for thick foam or wooden inlays.

Key Takeaway: Utilizing digital manufacturing tools ensures that every insert in a 10,000-unit order is identical, maintaining your brand’s quality standards.

| Technology | Best For | Precision Level | |

|---|---|---|---|

| Laser Cutting | Intricate Shapes | Ultra-High | |

| Die-Cutting | Mass Production | Moderate to High | |

| Hand-Cutting | One-off Prototypes | Low |

How to make jewelry box inserts with branded organization?

You should integrate high-contrast color schemes and foil-stamped logos directly onto the insert surface to reinforce brand identity. When planning how to make jewelry box inserts, organization should always serve the visual hierarchy of the product. By using dark velvet against brilliant diamonds, as seen in our professional Custom Necklace Boxes , you create an immediate focal point that draws the eye.

Why is contrast important in insert design?

Contrast isn’t just aesthetic; it’s functional. A white gold ring on a white silk insert disappears, whereas the same ring on a deep emerald or charcoal velvet insert appears larger and more brilliant.

How can you use inserts to upsell multi-piece sets?

Designing “companion slots” within a single insert encourages customers to purchase matching earrings or a pendant for their ring. This tiered organization turns a simple box into a complete jewelry wardrobe.

Now, consider this: Your packaging is a silent salesperson that works long after the customer leaves the store.

- Use foil stamping for luxury brand logos.

- Choose complementary colors (e.g., gold foil on navy velvet).

- Create tiered platforms for a 3D visual effect.

- Include a branded care card slot behind the insert.

Key Takeaway: Strategic organization and branding on the insert itself elevate the customer’s perception of the jewelry’s worth and your company’s professionalism.

| Branding Element | Implementation | Impact | |

|---|---|---|---|

| Foil Stamping | Applied to velvet/card | High-end brand recognition | |

| Tiered Levels | Stacking foam layers | Dynamic visual interest | |

| Tone-on-Tone | Embossing same-color logos | Subtle, sophisticated luxury |

How to make jewelry box inserts using sustainable methods?

You can transition to biodegradable materials like molded pulp, FSC-certified paperboard, and organic cotton linings to meet modern ESG standards. The demand for eco-friendly solutions has changed how to make jewelry box inserts, as consumers now expect luxury to be sustainable. Recycled cardboard can be layered to provide the same rigidity as plastic foam while remaining fully recyclable.

Can sustainable inserts still look “luxury”?

Yes, by using textured kraft paper or hemp-based velvet, you can achieve a “natural luxury” aesthetic that resonates with eco-conscious demographics. These materials often feel warmer and more artisanal than standard petroleum-based foams.

What are the benefits of molded pulp?

Molded pulp is made from recycled paper and can be pressed into precise shapes for rings and necklaces. It is exceptionally durable and can be dyed with soy-based inks to match any brand palette while being 100% compostable.

It gets better: Sustainability is no longer a niche; it is a prerequisite for entry into many premium retail markets.

- FSC-certified paper for structural bases.

- Plant-based foams (soy or algae) for cushioning.

- Organic cotton or silk for protective linings.

- Recyclable corrugated layers for impact resistance.

Key Takeaway: Eco-friendly inserts offer a competitive edge by aligning your brand with the environmental values of the modern luxury consumer.

| Sustainable Material | Traditional Alternative | Environmental Impact | |

|---|---|---|---|

| Molded Pulp | Plastic Trays | Biodegradable/Recyclable | |

| Hemp Velvet | Polyester Velvet | Renewable Resource | |

| Recycled Card | EVA Foam | Plastic-Free |

How do you maintain how to make jewelry box inserts?

You must use specialized lint rollers and soft-bristled brushes to remove dust and debris from velvet and flocking. Maintenance is a vital part of knowing how to make jewelry box inserts last, especially for showroom displays that are handled daily. Keeping the inserts pristine ensures that the jewelry always looks “new” and well-cared for.

How do you fix matted velvet fibers?

If the velvet fibers become crushed or matted due to heavy jewelry, you can use a small amount of steam and a soft brush to lift the pile. This “grooming” process restores the original sheen and friction properties of the fabric.

What is the best way to handle white or cream inserts?

Lighter colors are prone to showing fingerprints and oils. You should always handle these inserts with jewelry gloves and keep them in a dust-free environment when not on display to prevent yellowing or staining.

Think about this: A dusty or stained insert immediately devalues the jewelry it carries.

- Weekly dusting with a high-tack lint roller.

- Monthly grooming with a soft-bristled jewelry brush.

- Quarterly inspections for adhesive failure or fabric wear.

- Storage in airtight display cases to prevent oxidation.

Key Takeaway: Proactive maintenance of your jewelry inserts preserves the luxury experience and prevents the transfer of dirt to the products.

| Maintenance Task | Frequency | Recommended Tool | |

|---|---|---|---|

| Surface Dusting | After every handling | Lint Roller | |

| Pile Restoration | Monthly | Soft Brush/Steam | |

| Structural Check | Quarterly | Visual Inspection |

What are creative ways for how to make jewelry box inserts?

You can experiment with stackable modular trays and hidden compartments to create a multi-functional storage solution. Thinking outside the box regarding how to make jewelry box inserts allows you to provide added value to the customer, such as integrated travel pouches or magnetic modular sections. These innovations turn a simple box into a cherished heirloom.

How do modular inserts work for retailers?

Modular inserts allow you to swap out compartments based on the inventory you are displaying. You can have a “ring day” and an “earring day” using the same outer boxes simply by switching the internal foam pads, reducing your overhead costs.

Can you integrate tech into inserts?

High-end brands are now incorporating LED lighting or NFC tags into their inserts. LED lights are activated upon opening to enhance the diamond’s fire, while NFC tags can link the customer’s phone to an online certificate of authenticity.

The bottom line: Innovation in packaging is the fastest way to differentiate your brand in a crowded market.

- Magnetic modular sections for versatile storage.

- Integrated LED lighting for diamond enhancement.

- Hidden “secret” compartments for extra security.

- Reversible inserts with different colors on each side.

Key Takeaway: Creative, tech-forward inserts transform packaging from a cost center into a powerful marketing and engagement tool.

| Creative Concept | Implementation | Target Audience | |

|---|---|---|---|

| Modular Trays | Swappable foam sections | Professional Retailers | |

| LED Lighting | Battery-powered lid sensors | High-End Engagement | |

| NFC Integration | Embedded chips in the base | Tech-Savvy Millennials |

Frequently Asked Questions

1. What is the most cost-effective material for bulk jewelry inserts?Die-cut flocked paperboard is generally the most economical choice for high-volume B2B orders. It provides a velvet-like appearance at a fraction of the cost of real fabric and foam.

2. How do I prevent my jewelry from tarnishing inside the box?You should use anti-tarnish cloth or add a small 3M anti-tarnish strip behind the insert. These materials absorb hydrogen sulfide and other atmospheric pollutants that cause metal discoloration.

3. Can I make jewelry box inserts without using any glue?Yes, you can achieve a “friction-fit” by sizing the insert exactly 0.5mm larger than the internal box dimensions. The tension between the insert and the box walls will hold it securely in place.

4. What foam density is best for heavy metal watches or bracelets?For heavy items, you should use high-density EVA foam (approx. 30-40 kg/m³). This provides enough resistance to prevent the item from “bottoming out” against the rigid base of the box.

5. How can I customize my inserts for a unique brand look?Beyond color and material, you can use specialized die-cutting to create geometric patterns, or employ laser engraving to etch your logo directly into the foam or velvet surface.

Mastering the art of custom organization is a journey that begins with quality materials and ends with a satisfied customer. To explore how we can help you build the perfect housing for your collection, contact us today for a professional consultation.