Selecting the right jewelry boxes requires evaluating the balance between aesthetic appeal, structural protection, and the specific brand narrative you wish to convey to your B2B clients. Many jewelry retailers struggle with generic packaging that fails to elevate the product or withstand the rigors of global logistics. This lack of distinction can lead to a significant drop in perceived value, making your high-end collections appear ordinary or poorly cared for. By strategically selecting a premium jewelry box material , you can transform the unboxing experience into a powerful marketing tool that reinforces your brand’s commitment to quality.

Why is jewelry box material critical for brand identity?

Selecting the right material communicates your brand’s market position and justifies premium pricing through tactile feedback. You must strategically evaluate your jewelry box material choices to ensure they reflect your professional B2B standards. This physical touchpoint acts as a silent ambassador before the jewelry is even revealed.

Look at this:The physical weight and surface finish of your packaging are primary indicators of quality in a retail environment.

The Psychology of Tactile Surfaces

When a customer holds a box, their brain immediately processes the texture and temperature of the surface. A cold, smooth lacquered wood feels inherently more valuable than a lightweight, thin plastic shell. Natural grains and soft-touch coatings provide a sense of stability and modern innovation.

Does consistency matter across product lines?

Maintaining a unified material choice across your entire inventory ensures a cohesive brand image for your clients. Whether selling a simple silver charm or a diamond necklace, the packaging should feel like it belongs to the same family. Unified textures help in brand recall and simplify the procurement process for your warehouse.

Key Takeaway: A well-chosen material ensures your brand identity is reinforced through sensory cues that build trust and justify your market positioning.

| Identity Factor | Impact Level | Preferred Material Example | |

|---|---|---|---|

| Perceived Value | High | High-gloss Lacquered Wood | |

| Brand Modernity | Medium | Soft-touch Matte Paper | |

| Artisanal Feel | High | Textured Linen or Kraft |

How to select jewelry box material for high-end rings?

Choosing materials for rings focuses on structural density and precision-cut inserts that provide a secure, high-end “snap” when closed. Since rings are often the centerpiece of emotional milestones, the material must feel substantial despite its small size. The internal fit must be tight to prevent the ring from shifting during transit.

Think about this:A ring box’s material must provide a satisfying “click” to signal quality and security to the recipient.

Structural Integrity of Ring Bases

The base material determines the weight and how the box feels in the hand during a proposal. Most premium ring boxes utilize a high-density plastic or a wooden core to achieve this stability. Wooden cores offer a traditional, heavy-set feel, while plastic allows for more precise hinge mechanisms.

What about interior lining and ring slits?

The material inside the box is just as important because it directly touches the precious metal. You should choose a fabric like velvet that is soft enough to prevent scratches but firm enough to hold the ring upright. Microfiber is a modern alternative that offers superior cleaning properties for the jewelry surface.

Key Takeaway: For rings, prioritize high-density cores and light-absorbing interior fabrics to maximize the visual impact of the jewelry.

| Feature | Best Material | Benefit | |

|---|---|---|---|

| Structural Weight | Solid Wood | Provides a luxury hand-feel | |

| Hinge Reliability | ABS Plastic | Ensures a consistent, sharp snap | |

| Gemstone Contrast | Black Velvet | Enhances diamond brilliance |

What is the best jewelry box material for eco-friendly packaging?

FSC-certified paper and high-density recycled cardboard are the gold standards for brands prioritizing sustainability without sacrificing luxury aesthetics. As global B2B trends shift toward sustainability, choosing an eco-friendly jewelry box material is essential for modern retailers. You can achieve a high-end look using organic fibers and soy-based inks.

It gets better:Sustainable materials often have unique textures that convey a sense of authenticity and modern ethics to your customers.

Recycled Paperboard and Kraft

High-density recycled cardboard offers surprising structural strength and can be laminated with organic papers for a premium finish. Kraft paper provides a raw, natural aesthetic popular with boutique brands looking for an artisanal feel. Rigid paperboard can be made from 100% post-consumer waste while remaining durable.

Are natural inserts truly effective?

Traditional foam inserts are being replaced by molded pulp or precision-folded paper that holds items securely without plastic. This shift is crucial for brands targeting demographics that value corporate social responsibility. Organic cotton and FSC paper inserts are soft, reusable alternatives that protect the jewelry effectively.

Key Takeaway: Sustainable packaging relies on FSC-certified substrates and the elimination of non-recyclable plastics and foams.

| Eco-Component | Recommended Material | Recyclability | |

|---|---|---|---|

| Box Shell | FSC-Certified Paperboard | 100% | |

| Internal Cushion | Molded Paper Pulp | 100% | |

| Printing | Soy-based or Water-based Ink | High |

Which jewelry box material supports heavy necklaces?

Heavy necklaces require reinforced rigid board or double-walled construction to prevent bowing and ensure the frame stays intact during transit. Because necklace boxes are larger, they have more surface area that can be damaged if the substrate is too thin. You need a reinforced structure that maintains its shape even when stacked in high volumes.

Look at this:A necklace box is not just a container; it is a structural frame that prevents tangling and damage.

Reinforced Rigid Board Construction

For large-format jewelry, standard paperboard often isn’t enough to support the weight of heavy pendants. You need a greyboard with a thickness of at least 1200gsm to ensure the sides do not cave in. Reinforced corners are also vital to prevent the “crushing” effect during bulk shipping to your retail locations.

How do synthetic leathers improve durability?

Synthetic leather is an excellent choice for large boxes because it resists the stretching and tearing common with paper. It provides a wipe-clean surface that is essential for maintaining a professional look in long-term displays. PU leather offers the appearance of real leather with much higher consistency and lower cost.

Key Takeaway: Use reinforced rigid board and PU leather for necklace boxes to ensure structural integrity and a premium, durable finish.

| Requirement | Material Choice | Performance | |

|---|---|---|---|

| Frame Rigidity | 1200gsm Rigid Board | Prevents bowing under weight | |

| Surface Durability | PU Synthetic Leather | Resists scratches and stains | |

| Tangle Prevention | Padded Suede Insert | Holds chains firmly in place |

How does material influence the tactile customer experience?

The jewelry box material creates an emotional connection through sensory cues like soft-touch coatings and embossed textures. In a professional retail setting, the physical feel of a box creates a lasting impression of quality before the jewelry is seen. You should choose materials that invite touch and provide a sense of comfort and luxury.

The kicker is this:The unboxing phenomenon relies heavily on the sounds and textures of the packaging materials you choose.

Soft-Touch and Velvet Coatings

Modern materials allow for paper coatings that feel like velvet or soft rubber, offering a sleek, high-tech aesthetic. Soft-touch laminates resist fingerprints and look pristine even after multiple handlings in a store. Flocked paper provides a luxurious feel at a fraction of the cost of premium fabrics.

Why use embossed and debossed textures?

Adding a physical texture to the surface of the box through embossing makes a brand feel more established. Linen textures convey organic craftsmanship, while pebbled finishes provide a classic leather look that is timeless. These details add a layer of depth that a flat, printed surface cannot match.

Key Takeaway: Focus on specialty coatings and embossed textures to create a multi-sensory unboxing experience that delights customers.

| Tactile Sensation | Material/Finish | Perception | |

|---|---|---|---|

| Velvety Smoothness | Soft-touch Laminate | Modern & Innovative | |

| Rich Texture | Deep Grain Embossing | Established & Traditional | |

| Warmth | Natural Wood/Fabric | Organic & Personal |

Can you customize material to match your brand colors?

You can certainly customize materials using Pantone-matched dyes and specialized printing techniques to ensure total brand consistency. Customization allows you to maintain a strict visual identity across all your packaging formats. You are not limited to stock colors when ordering in wholesale volumes for your business.

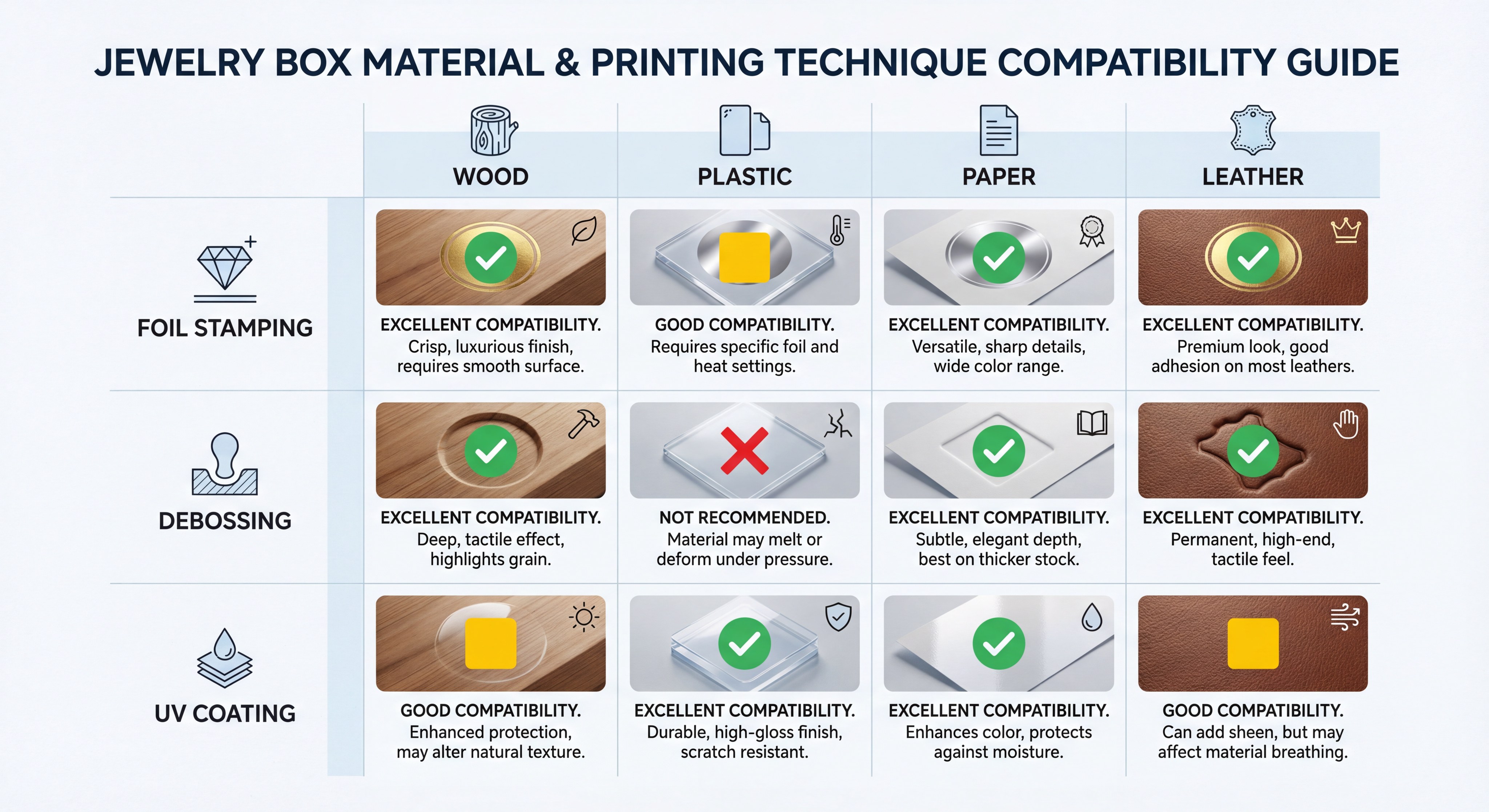

But wait, there’s more:Customization also extends to how the material reacts to branding techniques like hot foil stamping or UV coating.

Custom Dyeing and Substrate Matching

For high-volume orders, the paper or fabric can be dyed at the pulp level to ensure deep, consistent color. This prevents white edges from showing when the paper is folded over the box corners. Custom-dyed fabrics ensure that your brand’s specific shades are perfectly represented in every unit.

Is the material compatible with your branding?

Different materials react differently to branding techniques such as hot foil stamping or debossing. Smooth paper is best for intricate, fine-line foil stamping, while textured paper works better for bold, deep debossing. Choosing the right substrate ensures your logo appears crisp and professional every time.

Key Takeaway: Work with a manufacturer who can provide pulp-dyed materials and color-matching services for a truly bespoke brand experience.

| Customization Type | Method | Best For | |

|---|---|---|---|

| Color Matching | Pantone Pulp Dyeing | Complete Brand Uniformity | |

| Logo Application | Hot Foil Stamping | High-contrast Branding | |

| Unique Texture | Custom Embossing | Exclusive Brand Identity |

What are the durability differences between material options?

Comparing jewelry box material options reveals that PU leather and solid wood offer the highest resistance to humidity and wear over time. Durability is about resistance to environmental factors like UV light and oils from the skin. You must select materials that can withstand the shipping process and long-term retail display.

Check this out:A box that falls apart or discolors quickly reflects poorly on the quality of the jewelry inside.

Comparison of Material Longevity

Different materials have different lifespans before they start to show signs of wear in a retail environment. Solid wood can last for decades, while PU leather is highly resistant to scratches and moisture. Standard cardboard is cost-effective but can become soft at the edges over time if handled frequently.

Does the material protect against tarnish?

The chemical composition of the internal materials is critical for protecting precious metals from oxidation. Acid-free paper is essential for preventing the yellowing of the box and the tarnishing of the jewelry. Neutral adhesives prevent the peeling effect often seen in low-quality boxes stored in humid conditions.

Key Takeaway: Prioritize PU leather and acid-free internal materials for the best balance of retail durability and jewelry protection.

| Material | Moisture Resistance | Scratch Resistance | Best Use Case | |

|---|---|---|---|---|

| PU Leather | High | High | Retail & Storage | |

| Wood | Medium | Medium | Luxury Gifts | |

| Paper/Board | Low | Low | E-commerce Shipping |

How does jewelry box material impact the shipping cost?

Material weight and volume directly dictate your logistics overhead, making lightweight high-density boards essential for cost-efficient B2B operations. For businesses shipping thousands of units, even a few grams of difference per box can result in significant annual savings. You must find the balance where the material feels premium but remains lightweight.

The bottom line?Every millimeter of thickness and gram of weight adds to your final shipping invoice.

The Rise of Lightweight High-Density Materials

Advancements in material science have led to the development of thinner, higher-density paperboards for luxury packaging. These provide a rigid feel with a lower profile, allowing for more units per shipping pallet. Lightweight materials also reduce the carbon footprint associated with global air freight logistics.

Can collapsible designs save you money?

High-quality materials are now being used in collapsible box designs that ship flat and pop into shape at the store. This reduces inbound shipping costs by up to 70% while saving valuable warehouse space. High-quality magnets ensure the box feels rigid and premium once it is assembled for the customer.

Key Takeaway: Optimize shipping costs by choosing high-density, thin-walled materials or collapsible designs that maximize pallet efficiency.

| Material Factor | Cost Impact | Solution | |

|---|---|---|---|

| Material Weight | High | Use High-density Paperboard | |

| Box Volume | Very High | Slim-profile Designs | |

| Storage Space | Medium | Collapsible/Flat-pack Styles |

Which material is most suitable for luxury watch presentation?

High-gloss lacquered wood or heavy-weight synthetics are the premier jewelry box material choices for horological items due to their furniture-grade finish. Watches are heavier and more complex than most jewelry, so the box must be exceptionally robust. You should look for materials that convey a sense of mechanical excellence and tradition.

Here is the kicker:A watch box is often kept as a permanent storage case, so the material must be furniture-grade quality.

High-Gloss Lacquered Wood Cores

Lacquered wood is the gold standard for luxury watches because of its mirror-like finish and substantial weight. It provides a protective “vault” feel that protects the watch from external impacts. Multiple layers of lacquer create a deep, lustrous finish that appeals to high-end collectors and enthusiasts.

Why choose microfiber for watch linings?

The interior of a watch box must be non-abrasive to protect the case, crystal, and strap from damage. Microfiber is popular because it can be used to wipe fingerprints off the watch while providing excellent cushioning. Padded pillows must be made of materials that maintain their shape and do not compress permanently.

Key Takeaway: For watches, choose lacquered wood or high-density PU with microfiber interiors for a professional, long-lasting presentation.

| Feature | Watch Box Material | Reason | |

|---|---|---|---|

| Exterior Shell | Lacquered Wood | Traditional luxury and weight | |

| Interior Liner | High-grade Microfiber | Protects against micro-scratches | |

| Support | Padded Pillow | Fits various wrist sizes securely |

How should you evaluate material for long-term storage?

You should prioritize UV stability and chemically neutral adhesives to ensure materials do not fade or cause jewelry oxidation over several years. Fine jewelry is often kept in its original box for a lifetime, so the material must be physically resilient. You need to ensure that colors won’t fade and adhesives won’t dry out.

Look at it this way:Your packaging is a long-term investment in your customer’s jewelry collection.

UV Stability and Fade Resistance

Exposure to sunlight in retail windows can cause low-quality materials to fade or yellow quickly. You should select materials treated for UV stability to keep colors vibrant for years to come. High-quality synthetic leathers are often more color-stable than natural dyed leathers over long periods.

Final Checklist for Material Selection

To choose the best material for your brand, you must audit your needs against specific performance criteria.

- Is the material chemically neutral to prevent tarnishing of the jewelry?

- Does the weight match the perceived value of your price point?

- Is the material durable enough for your intended global shipping method?

- Does the material meet your brand’s specific sustainability requirements?

Key Takeaway: Long-term storage requires UV-stable, chemically neutral materials and high-quality adhesives to ensure the box remains pristine.

| Storage Factor | Material Requirement | Goal | |

|---|---|---|---|

| Color Fastness | UV-Stable Pigments | Prevent fading over years | |

| Structural Bond | High-Grade Adhesives | Prevent peeling and bubbling | |

| Jewelry Safety | Acid-Free Lining | Prevent metal oxidation |

Our vision is to redefine the jewelry packaging industry through innovation, quality, and sustainable practices. We are committed to providing retailers with packaging solutions that tell a story of luxury and care. For more information on how we can help you select the perfect packaging for your next collection, please contact us today .

FAQ

Can I customize the interior material for different jewelry types?Yes, you can select specific linings like velvet, microfiber, or silk for each product category to ensure optimal protection and presentation for your inventory.

What’s the best material for shipping jewelry internationally?High-density rigid paperboard is the best choice as it offers high impact resistance while remaining lightweight to minimize international freight costs.

Can I get eco-friendly materials that still look luxury?Absolutely; by using FSC-certified textured papers and high-end printing techniques like foil stamping, eco-friendly boxes can look indistinguishable from traditional luxury packaging.

How do I know if a jewelry box material is anti-tarnish?You should look for materials labeled as “acid-free” and “sulfur-free,” as these chemical properties prevent the oxidation of silver and gold items.

Is PU leather better than real leather for jewelry boxes?For B2B purposes, PU leather is often superior because it offers better color consistency and higher moisture resistance while maintaining a premium luxury feel.